| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

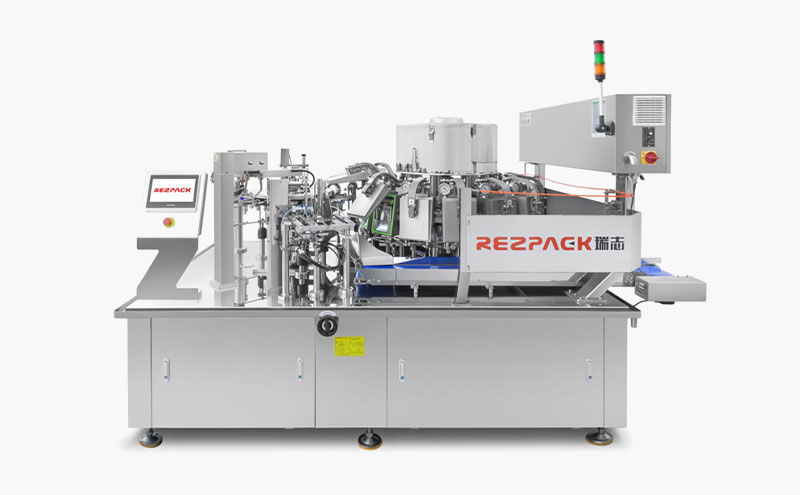

In the fast-paced world of manufacturing and packaging, efficiency, precision, and reliability are essential. One of the most innovative solutions to emerge in recent years is the Pick-Fill-Seal Machine for Preformed Bags. This advanced equipment has changed the way the industry approaches packaging, especially preformed bags. In this article, we will explore what this machine is, how it works, its key features, and the benefits it brings to various industries.

The Pick-Fill-Seal Machine for Preformed Bags is a state-of-the-art packaging system designed to automate the process of picking, filling, and sealing preformed bags to create efficient sealed packaging. Unlike traditional form-fill-seal machines that use roll stock to make bags, this machine is specifically designed to work with preformed bags, providing greater flexibility and efficiency for certain applications.

The machine is ideal for industries that require high-speed, high-precision packaging, such as food and beverage, pharmaceuticals, pet food, and personal care products. Its ability to handle a wide range of bag sizes, shapes, and materials makes it a versatile solution for a variety of packaging needs.

How does a pre-made bag pick-fill-seal machine work?

A rotary Premade Pouch Pick Fill Seal Machine operates through a series of highly coordinated steps:

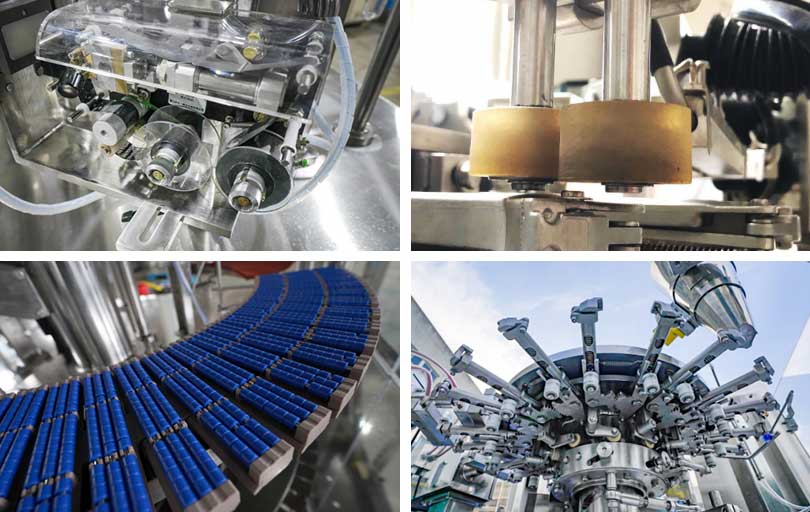

1. Bag Picking: The machine picks up the pre-made bag from a stack or magazine using a robotic arm or suction system. This ensures precise handling and minimizes the risk of bag damage.

2. Bag Opening: After picking up the bag, the machine opens it using a combination of robotic fingers. This step is critical to ensure the bag is ready for filling.

3. Product Filling: The opened bag is then moved to a filling station where the product is dispensed with high precision. The machine can handle a wide range of products including liquids, powders, granules and solids.

4. Bag Sealing: After filling, the bag is transferred to a sealing station where it is sealed using heat, pressure technology, depending on the bag material and product requirements.

5. Discharge: The sealed bag is then discharged onto a conveyor or collection bin ready for further processing or packaging.

1. High-speed operation: The machine can process hundreds of bags per minute, greatly improving production efficiency.

2. Versatility: It can handle various types of bags, including stand-up pouches, flat bags, spouted bags, etc. It also supports a variety of materials, such as plastic, foil, and biodegradable films.

3. Precision filling: The advanced batching system ensures accurate filling, reduces product waste, and ensures consistent packaging weight.

4. User-friendly interface: The machine is equipped with an intuitive touch screen interface for easy operation and adjustment of settings.

5. Hygienic design: Made of food-grade materials, the machine is easy to clean and meets strict hygiene standards, suitable for food and pharmaceutical applications.

6. Customization options: The machine can be customized to specific production requirements, including bag size, filling volume, and sealing method.

1. Increased productivity: By automating the packaging process, the machine significantly reduces labor costs and increases output.

2. Improved product quality: Precise filling and sealing ensures consistent and safe product packaging, maintaining its quality and shelf life.

3. Reduced waste: Accurate dosing and minimal product spillage help reduce material and product waste.

4. Flexibility: The ability to handle different bag types and sizes allows manufacturers to quickly adapt to changing market demands.

5. Cost-effectiveness: While the initial investment may be significant, the long-term savings in labor, materials, and increased production efficiency make it a cost-effective solution.

Rotar pre-made bag pick-fill-seal machines are widely used in various industries, (Click to get the solution):

Food and beverage: For packaging snacks, sauces, beverages, and ready-to-eat foods.

Pharmaceuticals: For packaging powders, tablets, and liquid medications.

Pet food: For packaging dry and wet pet food.

Personal care: For packaging shampoos, lotions, and other cosmetics.

With over 33 years of experience in the packaging industry and 20 years of focus on rotary packaging machines, Rezpack has over 3,000 customers in Europe, the United States, Australia and Asia who trust Rezpack machines to meet their packaging needs

Our rotary pre-made bag pick fill seal machines can be tailored to your product and packaging requirements. Whether you are packaging granules, powders or liquids, our machines can handle a wide range of bag types, including stand-up bags, zipper bags, spout bags and shaped bags. We will provide a customized solution within 24 hours, taking into account your product characteristics, bag type, size and weight.

We have successfully implemented packaging solutions for a variety of products, including cereals, coffee, nuts, jerky, tea, potato chips, flour, spices, water, oil and detergents. Our rotary packaging machines support a variety of packaging bag sizes, which can be easily adjusted through the touch screen, and the settings can be saved for future use. If you are still struggling to choose the right machine, our technicians will provide you with the best solution.

| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

| Bag Width Range | 180-300 mm | Weight | 1800 kg |

| Bag Length Range | 150-450 mm | Total power | 3.62 kw |

| Filling weight | ≤ 2500 g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 50 bags/min | Dimensions | 2080 mm*1720 mm*1650mm |

| Bag Width Range | 240-400 mm | Weight | 2500 kg |

| Bag Length Range | 150-600 mm | Total power | 3.62 kw |

| Filling Range | ≤ 5000g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 30 bags/min | Dimensions | 2150 mm*2020 mm*1700 mm |

GET A QUOTE