| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

In today’s fast-paced production environment, efficiency and product quality are key to a company’s success. Vacuum packaging, as an advanced packaging technology, not only extends the shelf life of products such as food, pharmaceuticals, and electronic components but also enhances market competitiveness. However, many companies often hesitate when considering whether to invest in vacuum packaging equipment. This article will explore the value of vacuum packaging, focusing on the features of our rotary vacuum packaging machine, and discuss whether vacuum packaging is worth the investment.

Vacuum packaging works by removing air from the packaging bag and sealing it, creating an oxygen-free environment that effectively prevents oxidation, spoilage, or moisture damage. This technology is widely used in industries such as food, pharmaceuticals, electronics, and chemicals, offering the following core advantages:

Extended Shelf Life: Vacuum packaging significantly extends product shelf life, reducing waste and lowering inventory pressure.

Preserves Product Quality: By preventing oxidation and contamination, vacuum packaging maintains product freshness, taste, and nutritional value.

Enhances Product Image: Vacuum packaging gives products a cleaner, more professional appearance, boosting consumer appeal.

Saves Transportation and Storage Space: Vacuum-packed products take up less space, making them easier to transport and store, thereby reducing logistics costs.

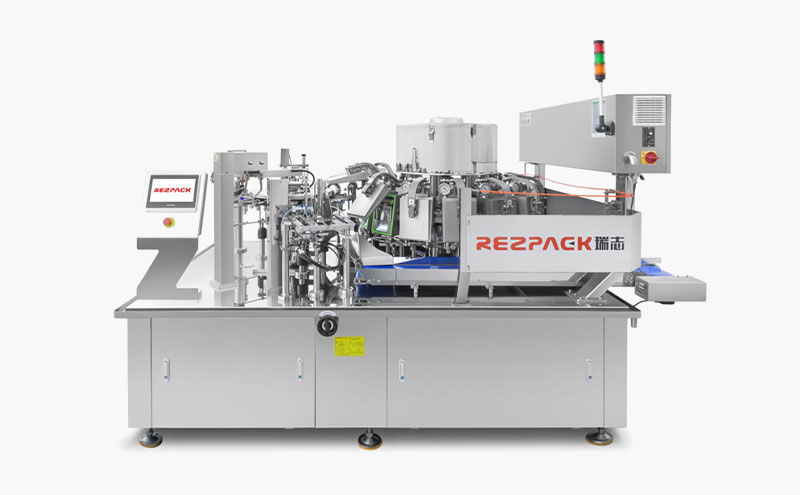

With the advent of Industry 4.0, automated equipment has become crucial for improving production efficiency and reducing labor costs. Our rotary vacuum packaging machine, developed in line with this trend, offers the following standout features:

The machine uses groove clamps to complete all actions, which are more durable and stable compared to traditional end cam designs.

It eliminates the need for spring returns, reducing the likelihood of mechanical failures and further enhancing production efficiency and equipment lifespan.

The RZ10-100-14ZK Rotary Vacuum Packing Machine is equipped with a comprehensive prevention system that detects whether bags are open or insufficiently opened.

If a bag does not meet filling requirements, the machine automatically returns it to the first station for re-filling, preventing empty bags from entering the sealing process and reducing material waste and production costs.

The machine is built with high-precision components and an advanced control system, ensuring long-term stable operation.

Automated operations reduce the need for manual intervention, minimizing the risk of human error.

The machine is suitable for various industries, including food, pharmaceuticals, and electronics, meeting diverse packaging needs.

Users can adjust parameters based on product characteristics for customized packaging.

As a technology-driven company with 32 years of experience in the packaging industry, we are committed to providing professional, comprehensive packaging solutions. Our advantages include:

Extensive Industry Experience: With decades of experience, we deeply understand customer needs and can offer tailored solutions.

Global Service Network: Our machines are exported to over 40 countries, serving more than 3,000 companies worldwide, giving us rich experience in international sales and service.

R&D and Manufacturing Strength: We integrate R&D, manufacturing, sales, and after-sales services to ensure every machine meets international standards.

Comprehensive After-Sales Support: We provide full technical support and service to ensure worry-free operation of our equipment.

From a long-term perspective, investing in vacuum packaging equipment is a wise decision. Here are some key reasons:

Cost-Effectiveness: Although the initial investment is high, automated vacuum packaging machines significantly reduce labor costs and material waste, offering a high return on investment over time.

Enhanced Competitiveness: Vacuum packaging improves product quality and shelf life, helping companies stand out in a competitive market.

Meeting Market Demand: As consumer demand for food safety and quality continues to rise, vacuum packaging has become a standard in many industries.

Sustainability: By reducing waste and extending product shelf life, vacuum packaging supports companies in achieving sustainability goals.

Vacuum packaging is not just a technology but a strategic choice for enhancing a company’s competitiveness. Our rotary vacuum packaging machine, with its high automation, intelligent prevention system, and stable performance, helps companies achieve efficient, low-cost packaging production. If you are looking for a reliable vacuum packaging solution, our machine is the ideal choice.

| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

| Bag Width Range | 180-300 mm | Weight | 1800 kg |

| Bag Length Range | 150-450 mm | Total power | 3.62 kw |

| Filling weight | ≤ 2500 g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 50 bags/min | Dimensions | 2080 mm*1720 mm*1650mm |

| Bag Width Range | 240-400 mm | Weight | 2500 kg |

| Bag Length Range | 150-600 mm | Total power | 3.62 kw |

| Filling Range | ≤ 5000g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 30 bags/min | Dimensions | 2150 mm*2020 mm*1700 mm |

GET A QUOTE