Capacity

Up To 95 BPM

Filling Volume

≤ 1500g

Bag Width

50-300mm

Bag Length

80-400mm

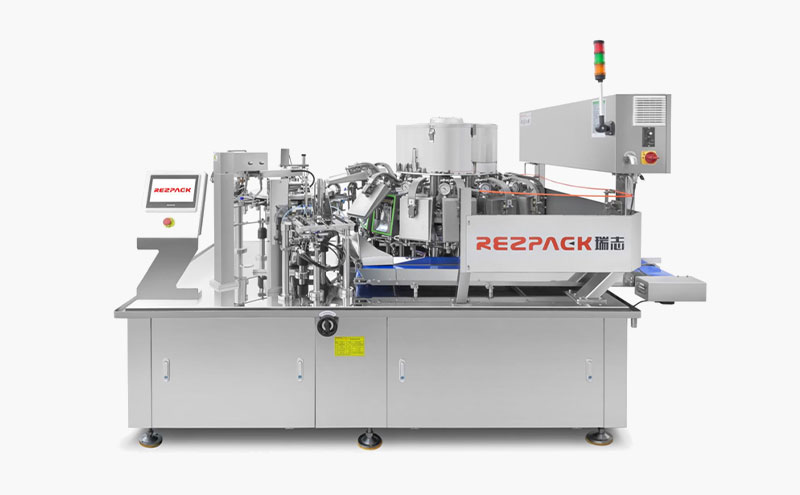

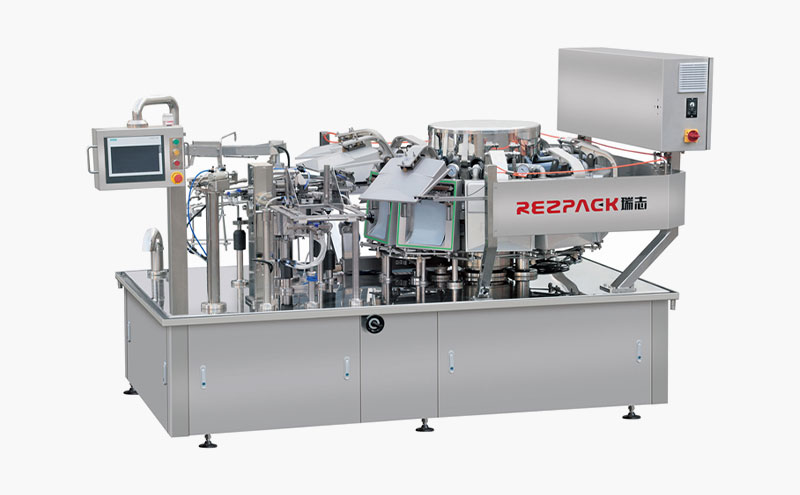

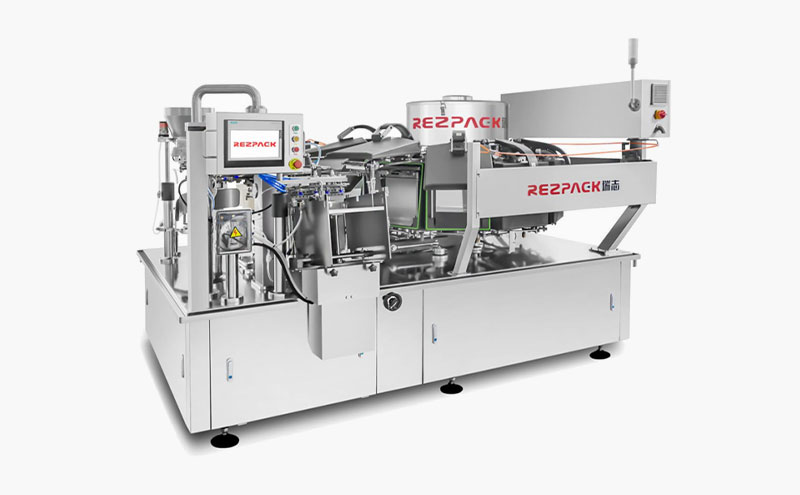

Rotary type fully-automatic vacuum packaging machine for various vacuum required products with all kinds of premade bags

Max speed to 120 bags/min

Bag width from 55mm to 300mm with different models

| Bag Width Range | 60-100 mm | Weight | 3000 kg |

| Bag Length Range | 80-190 mm | Total power | 11.27 kw |

| Filling Range | ≤200 g | Compress air | ≥ 0.5 m³/min |

| Max Speed | ≤100 bags/min | Dimensions | 2610 mm*1800 mm*1800 mm |

| Bag Width Range | 60-130 mm | Weight | 3100 kg |

| Bag Length Range | 100-190 mm | Total power | 11.27 kw |

| Filling Range | ≤ 300 g | Compress air | ≥ 0.5 m³/min |

| Packing Speed | ≤90 bags/min | Dimensions | 2610mm*1800mm*1800 mm |

| Bag Width Range | 80-140 mm | Weight | 3000 kg |

| Bag Length Range | 100-280 mm | Total power | 8.45 kw |

| Filling Range | ≤ 400 g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 80 bags/min | Dimensions | 2610 mm*1620 mm*1800 mm |

| Bag Width Range | 70-160 mm | Weight | 2600 kg |

| Bag Length Range | 100-210 mm | Total power | 7.37 kw |

| Filling Range | ≤400 g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤80 bags/min | Dimensions | 2600 mm*1900 mm*1800 mm |

| Bag Width Range | 120-200 mm | Weight | 3100 kg |

| Bag Length Range | 150-290 mm | Total power | 18.52 kw |

| Filling Range | ≤1200 g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤55 bags/min | Dimensions | 2910 mm*2060 mm*1850 mm |

| Bag Width Range | 120-240 mm | Weight | 3100 kg |

| Bag Length Range | 150-310 mm | Total power | 18.52 kw |

| Filling Range | ≤1500 g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤55 bags/min | Dimensions | 2910 mm*2060 mm*1850 mm |

| Bag Width Range | 160-300mm | Weight | 3400 kg |

| Bag Length Range | 150-390mm | Total power | 21.07 kw |

| Filling Range | ≤ 2500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤40 bags/min | Dimensions | 3180 mm*2310 mm*1900 mm |

| Bag Width Range | 60-95 mm | Weight | 5000 kg |

| Bag Length Range | 100-190 mm | Total power | 9.49 kw |

| Filling Range | ≤200 g | Compress air | ≥ 0.5 m³/min |

| Max Speed | ≤150 bags/min | Dimensions | 3340 mm*2130 mm*1800 mm |

| Models | RZ10-160E | RZ10-220E | RZ10-GS220E | RZ8-240E | RZ8-300E | RKA-825 | RZ8-S120 | RZ8-S170B | RZ10-M190 (Gusset Bag) |

RZ8-400E |

| Main Features | 10 stations, high speed | 10 stations, high speed | special for easy blocked products | widely application | widely application, wide width range | Korea Design,More advanced design with anti-collision features | double bag, high speed | double bag | Special for M type bags(gusset bags / square bag) | Big Bag with Big weight |

| Stations | 10 stations | 10 stations | 10 stations | 8 stations | 8 stations | 8 stations | 8 stations | 8 stations | 10 stations | 8 stations |

| Bag Width Range | 60-160 mm | 80-220 mm | 100-220 mm | 80-240 mm | 180-300 mm | 90-250 mm | 50-120 mm | 85-170 mm | 80-190 mm; side width ≤50mm | 240-400mm |

| Bag Length Range | 80-370 mm | 100-370 mm | 150-370 mm | 150-370 mm | 150-450 mm | 150-370 mm | 80-370 mm | 150-330 mm | 80-370 mm | 150-600mm |

| Filling Range | ≤ 500 g | ≤ 1500 g | ≤ 1000 g | ≤ 1500 g | ≤ 2500 g | ≤ 2500 g | ≤ 500 g | ≤ 1000 g | ≤ 500 g | ≤ 5000g |

| Max Speed depends on the bag and product |

≤ 100 bags/min | ≤ 60 bags/min | ≤ 45 bags/min | ≤ 60 bags/min | ≤ 50 bags/min | ≤ 60 bags/ min | ≤ 130 bags/min | ≤ 100 bags/min | ≤ 55 bags/min | ≤ 30 bags/min |

| Machine Weight | 1450 kg | 1800 kg | 1800 kg | 1500 kg | 1800 kg | 2700 kg | 2500 kg | 3000 kg | 2000 kg | 2500 kg |

| Machine Dimensions(mm) | 1840*1610*1550 | 1950*1740*1550 | 1950*1720*2420 | 1860*1520*1550 | 2080*1700*1650 | 2200*2050*2000 | 1850*2360*1550 | 2320*2060*1650 | 2260*1950*1550 | 2150*2020*1700 |

| Total Power | 3.22 kw | 3.42 kw | 9.47 kw | 3.02 kw | 3.62 kw | 4 kw | 5.41 kw | 5.41 kw | 4.12 kw | 3.62 kw |

| Driving Power | 380 V 3P 5W 50HZ (other power supply can be customized) | |||||||||

| Compress air requirement (provided by the customer) |

≥ 0.5 m³/min | ≥ 0.4 m³/min | ≥ 0.4 m³/min | ≥ 0.4 m³/min | ≥ 0.4 m³/min | ≥ 0.4 m³/min | ≥ 0.4 m³/min | ≥ 0.4 m³/min | ≥ 0.5 m³/min | ≥ 0.4 m³/min |

In today's fast-paced food industry, maintaining freshness and quality while extending shelf life is crucial. Vacuum packing has emerged as one of the most cost-effective methods for achieving these goals, particularly for perishable food products. The Rotary Vacuum Packaging Machine from Rezpack represents a significant advancement in this field, providing efficient, reliable, and economical solutions for a variety of applications.

Vacuum packing is economical and efficient for packaging perishable items due to low packing material costs, short processing times, and minimal investment in high-quality equipment. Beyond food products, our vacuum packaging machine is ideal for protecting daily necessities and living utensils like moisture-sensitive plastic items. The Rotary Vacuum Packaging Machine by Rezpack is a smart investment for businesses looking to enhance product management and packaging processes. With advanced technology, high production capacity, and versatile applications, it stands out as the best choice for optimal product preservation and efficiency. Experience the difference with our state-of-the-art rotary vacuum solution.

1. High Production Capacity: With speeds of up to 120 bags per minute, our machine can handle bag widths from 55mm to 300mm, making it perfect for high-volume production needs across diverse business sizes.

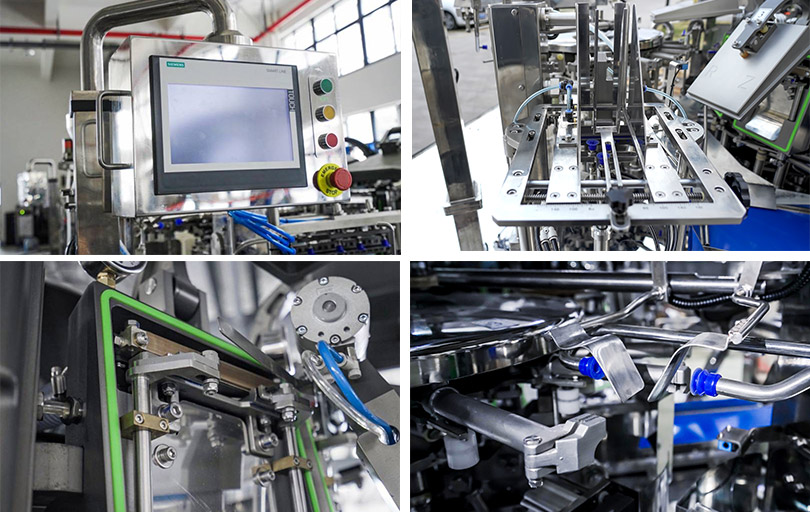

2. Hygienic and Quality Assurance: Designed for stringent hygiene requirements, the fully automatic system minimizes waste while maximizing productivity, ensuring safety for food and medical products alike.

3. User-Friendly Operation: The intuitive digital control unit (touch screen) simplifies adjustments and settings, allowing operators to maintain precision and consistency while reducing labor costs.

4. Quality and Reliability: Constructed from high-quality materials, the machine is engineered for consistent performance, effectively minimizing downtime and maintenance, making it a trusted choice for businesses.

5. Versatile and Flexible: Our rotary design can handle various bag shapes and sizes and integrates seamlessly with other production lines, significantly enhancing overall efficiency and product quality.

1. Quality Preservation: Vacuum packaging effectively reduces oxygen and humidity levels, preserving the color, aroma, taste, and nutritional value of food products, thereby enhancing their overall quality and flavor.

2. Product Integrity: The rotary vacuum machine protects products from external threats such as compression and vibration, ensuring that they maintain their integrity throughout the supply chain.

3. Versatility: This machine accommodates a wide range of product types, including solids, liquids, powders, and more, making it adaptable to diverse packaging needs.

1. Food Industry: Perfect for packaging meat, fish, dried fruits, vegetables, and instant foods.

2. Pharmaceuticals: Ideal for medicines, health supplements, and medical equipment packaging.

3. Other Industries: Effectively packages electronic products, metal items, precision machinery, and more.

GET A QUOTE