Capacity

12-20kw

Speed

4-6 p/min

Width of upper film

398mm-498mm

Width of lower film

423mm-523mm

Tray forming or skin packing with vacuum or gas filling

Max Film width 520mm

Keep the various porduct long fresh life

| Width of upper film | 398 mm | Vacuum | ≤ 200 Pa |

| Width of lower film | 423 mm | Compress air | ≥ 0.6 Mpa |

| Speed | 4-6 p/min | Capacity | 12-18 KW |

| Power | 380 V/50 Hz | Dimensions | 2250 kg |

| Width of upper film | 398 mm | Vacuum | ≤ 200 Pa |

| Width of lower film | 423 mm | Compress air | ≥ 0.6 Mpa |

| Speed | 4-6 p/min | Capacity | 12-18 KW |

| Power | 380 V/50 Hz | Dimensions | 2250 kg |

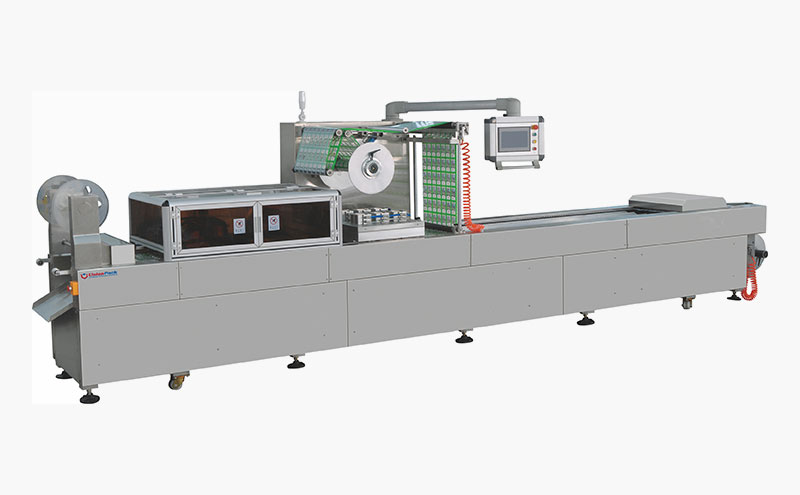

| Width of upper film | 498 mm | Vacuum | ≤ 200 Pa |

| Width of lower film | 523 mm | Compress air | ≥ 0.6 Mpa |

| Speed | 3-4 p/min | Capacity | 14-20 KW |

| Power | 380 V/50 Hz | Dimensions | 8000×1950×2050 mm |

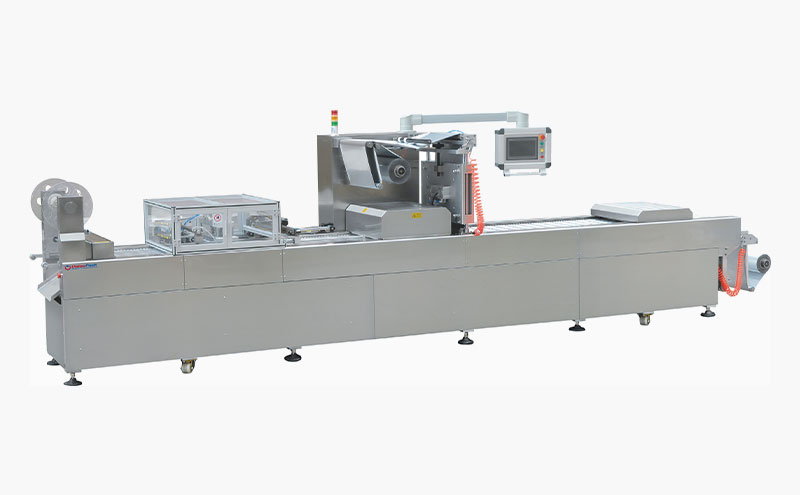

The Thermoforming Machine from Unionpack, the exclusive international service team for Rezpack, is a highly efficient packaging solution used across multiple industries, including food and non-food sectors. It is ideal for products such as meat, seafood, dates, biscuits, sauces, yogurt, fruits, vegetables, and even hardware and tools. Compared to other thermoforming machine manufacturers, our machine integrates globally recognized components like AIRTAC & SMC cylinders, Japan Yaskawa servo motors, Omron photocell tracking systems, BUSCH vacuum filters, SMC valves, and Schneider contactors, ensuring excellent stability and easy adjustments.

1. High Production Efficiency: The machine can produce over 10,000 bags per day, depending on product type, with fully automated operations, saving significant labor costs.

2. Customizable Design: Packaging quality is top-notch with a high degree of customization. The appearance, shape, and size of packaging can be tailored to meet various product requirements.

3. Hygienic and Safe Construction: The machine is enclosed with a stainless steel protective shield to prevent accidental contact with internal components. It’s equipped with distance sensors on the side doors, electrical cabinet, and safety covers to ensure safe operation. If the machine is opened during use, it stops automatically, reducing the risk of accidents.

4. Easy Operation: Full touch screen control with a user-friendly HMI interface allows for quick mold replacement and maintenance, providing a smooth experience for operators.

5. Self-Diagnosis & Fault Alarms: The machine has built-in fault alarms that notify operators of any issues, allowing timely repair and adjustment.

6. Automated Functions: The machine automates stretching, vacuuming, atmosphere adjustment (MAP), sealing, slitting, and film rewinding. It also supports integration with auxiliary equipment like robotic arms, automatic filling systems, multi-head weighers, conveyors, inkjet printers, labeling machines, UV sterilizers, and metal detectors.

The thermoforming machine is used in various industries, primarily food processing, to pack products in both soft and hard film vacuum or MAP packaging. It is particularly suitable for fresh food, cooked food, and snack products, delivering customized packaging solutions with faster production speeds. The high degree of customization and rapid production capabilities makes this machine an excellent investment for businesses in need of flexible and efficient packaging options.

For fresh and processed food items, the machine uses advanced thermoforming technology to ensure the product is securely packed, preserving freshness while maintaining a visually appealing, customizable design. It is designed to handle soft film vacuum, soft film MAP, hard film MAP, and vacuum body packaging, making it versatile for various packaging needs.

In conclusion, Unionpack’s Thermoforming Machine offers exceptional performance and is a perfect solution for businesses looking for automation, high output, and flexibility in their packaging processes.

GET A QUOTE