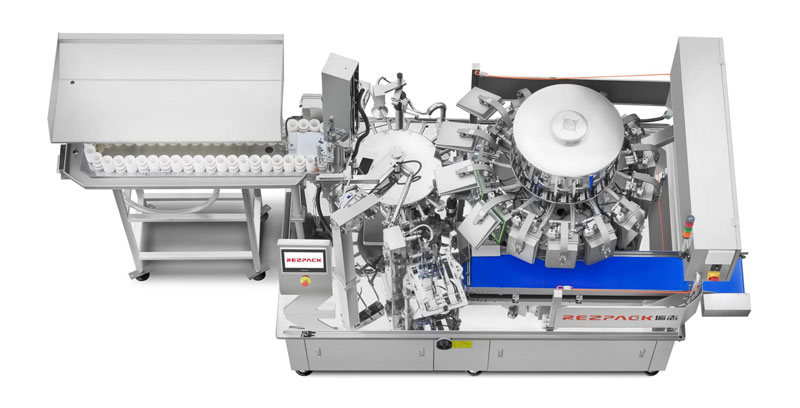

| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

Before vacuum packaging the corn, ensure that it is thoroughly cleaned and trimmed to remove any husks, silks, or debris. Proper handling and preparation help maintain the quality and appearance of the corn during packaging and storage.

Place the cleaned and prepared corn into the vacuum pouches, ensuring even distribution and avoiding overcrowding. Use the vacuum sealer machine to remove air from the pouches and create a tight seal.

Vacuum packaging is an effective method for extending the shelf life of fresh corn by removing air from the package, which slows down the degradation process and helps maintain freshness.

Use a vacuum machine specifically designed for packaging fresh produce. These machines remove air from the packaging material and create a vacuum seal to preserve the freshness of the corn.

Choose vacuum pouches made from food-grade materials that are suitable for fresh produce. These pouches should have excellent barrier properties to prevent oxygen ingress, which can cause spoilage.

Clearly label the vacuum-sealed corn pouches with essential information such as the type of corn, harvest date, and any storage instructions. This helps consumers make informed choices and ensures proper handling of the product.

Implement quality control measures to ensure the integrity of the vacuum-sealed corn packages. Inspect the seals for any signs of leakage or damage, and discard any packages that do not meet quality standards.

Store the vacuum-sealed corn pouches in a cool, dry place away from direct sunlight and heat sources. Proper storage conditions help maintain the quality and freshness of the corn for an extended period.

Features of Unionpack’s vacuum machine

Adjustable Vacuum Strength: Allowing users to customize the level of vacuum pressure according to the specific requirements of the product being packaged.

Durable Construction: These machines are typically built with durable materials such as stainless steel , ensuring longevity and reliability even under heavy usage.

User-Friendly Interface: Unionpack focuses on providing intuitive interfaces and user-friendly controls, making their vacuum machines easy to operate and adjust.

Customizable: According to the specific size of corn, different sizes of cutting measuring cups can be customized, truly controlling the details, making the product more stable.

Safety Features: Safety is paramount in packaging machinery, and Unionpack's vacuum machines often incorporate features such as emergency stop buttons, overheat protection, and safety interlocks to prevent accidents and ensure operator safety.

Versatility: Unionpack's vacuum machines may offer versatility in terms of the types of packaging they can handle, accommodating various bag sizes, materials, and product types.

High Production Capacity: Unionpack vacuum machines boasting high production capacities to meet the demands of large-scale packaging operations.

Easy Maintenance: Unionpack designs its machines with ease of maintenance in mind, often incorporating features such as removable sealing bars and accessible internal components for straightforward cleaning and servicing.

| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

| Bag Width Range | 180-300 mm | Weight | 1800 kg |

| Bag Length Range | 150-450 mm | Total power | 3.62 kw |

| Filling weight | ≤ 2500 g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 50 bags/min | Dimensions | 2080 mm*1720 mm*1650mm |

| Bag Width Range | 270-400 mm | Weight | 2500 kg |

| Bag Length Range | 150-600 mm | Total power | 3.62 kw |

| Filling Range | ≤ 5000g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 30 bags/min | Dimensions | 2150 mm*2020 mm*1700 mm |