| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

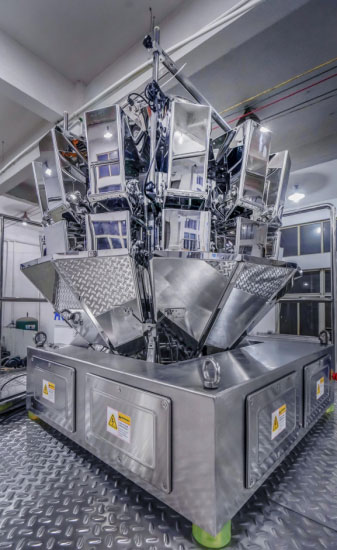

Weighers, commonly used in packaging industries, are precision instruments designed to accurately measure and dispense specific quantities of bulk materials.

High Accuracy: Weighers are equipped with high-precision load cells or sensors to ensure accurate measurement of the product's weight.

Multi-head Configuration: Many weighers utilize multiple weighing heads or buckets to weigh , increasing efficiency .

Fast Speed: Weighers are designed for high-speed operation, capable of quickly weighing and dispensing products.

Programmable Settings: They often feature programmable settings that allow operators to adjust parameters such as target weight, speed, and timing.

User-friendly Interface: Many weighers come with intuitive interfaces and touchscreen displays that make them easy to set up, operate, and monitor.

Product Memory: Some weighers have the capability to store settings, allowing for quick changeovers between different products.

Conveyors are critical components of industrial automation, facilitating the movement of goods and materials along a production line or within a facility.

Versatile Configurations: Conveyors come in a variety of Tray Type Conveyor,Bowl Type Conveyor,Auger Conveyor,Z-Type Conveyor,Bucket Conveyor,L Type Conveyor, allowing for versatile applications across different industries and environments.

Customizable Length and Width: Conveyors can be customized to specific length and width requirements to suit the layout and space constraints of the facility.

Adjustable Speed: Many conveyors offer adjustable speed settings, allowing operators to control the rate of material flow according to production demands.

Variable Load Capacity: Conveyors are designed to handle a wide range of load capacities,.

Modular Design: Conveyor systems feature a modular design, allowing for easy assembly, disassembly, and reconfiguration.

Adjustable Elevation: Conveyor systems offer adjustable height or incline options, enabling the transport of materials between different levels or elevations within a facility.

Safety Features: Conveyors often incorporate safety features such as emergency stop buttons, safety guards, and sensors to detect jams or obstructions and prevent accidents.

Fillers are essential machines in the packaging industry, used to accurately dispense and fill containers with various products such as liquids, powders, granules, and pastes.

Fillers are essential machines in the packaging industry, used to accurately dispense and fill containers with various products such as liquids, powders, granules, and pastes.

Fill Volume Accuracy: Fillers are designed to dispense precise amounts of product into containers, ensuring accuracy and consistency in fill volume.

Adjustable Fill Speed: Many fillers offer adjustable fill speeds to accommodate different product viscosities and container sizes.

Diverse Filling Technologies: Fillers utilize different filling technologies , enabling them to handle a wide range of products with varying properties.

Integrated Capping or Sealing: Fillers are equipped with integrated capping or sealing systems, allowing for seamless integration into complete packaging lines for a streamlined production process.

Automatic Level Control: Fillers may include automatic level control systems to maintain consistent product levels in the filling reservoir, ensuring accurate fills and preventing overfilling or underfilling of containers.

Operator-Friendly Interface: Fillers often feature user-friendly interfaces with touchscreen displays and intuitive controls, making them easy to set up, operate, and monitor by operators and production staff.

Integration with PLC Systems: Advanced fillers may be equipped with PLC systems for precise control and automation of filling parameters, allowing for customization and optimization of filling processes.

Metal detectors

Metal detectors are devices designed to detect the presence of metal objects in packaging.

Metal detectors are devices designed to detect the presence of metal objects in packaging.

Detection Sensitivity: Metal detectors offer adjustable sensitivity settings to detect metal objects of different sizes and compositions..

Target Discrimination: Detectors are equipped with target discrimination capabilities, which enable them to differentiate between various types of metal objects.

Automatic Calibration: Metal detectors may include automatic calibration features to ensure consistent performance over time.

Adjustable Conveyor Speed: Metal detectors used in conveyor systems often offer adjustable conveyor speeds, allowing operators to optimize throughput while maintaining reliable detection performance.

Integrated Reject Systems: Many metal detectors come with integrated reject systems that automatically divert or reject contaminated products from the production line.

User-Friendly Interface: Metal detectors typically feature user-friendly interfaces with intuitive controls and display screens. Operators can easily adjust settings, view detection results, and access diagnostic information through the interface.

Integration with Production Systems: Metal detectors can be seamlessly integrated with other production systems, such as conveyor belts, packaging machines, and sorting equipment. Integration facilitates automated processes and ensures smooth operation of the entire production line.

| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

| Bag Width Range | 180-300 mm | Weight | 1800 kg |

| Bag Length Range | 150-450 mm | Total power | 3.62 kw |

| Filling weight | ≤ 2500 g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 50 bags/min | Dimensions | 2080 mm*1720 mm*1650mm |

| Bag Width Range | 240-400 mm | Weight | 2500 kg |

| Bag Length Range | 150-600 mm | Total power | 3.62 kw |

| Filling Range | ≤ 5000g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 30 bags/min | Dimensions | 2150 mm*2020 mm*1700 mm |

GET A QUOTE