| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

Rotary packaging machines and vertical packaging machines are both widely used in the packaging industry, but they have different characteristics and applications. Here's a comparison of the two:

1.Design and Operation:

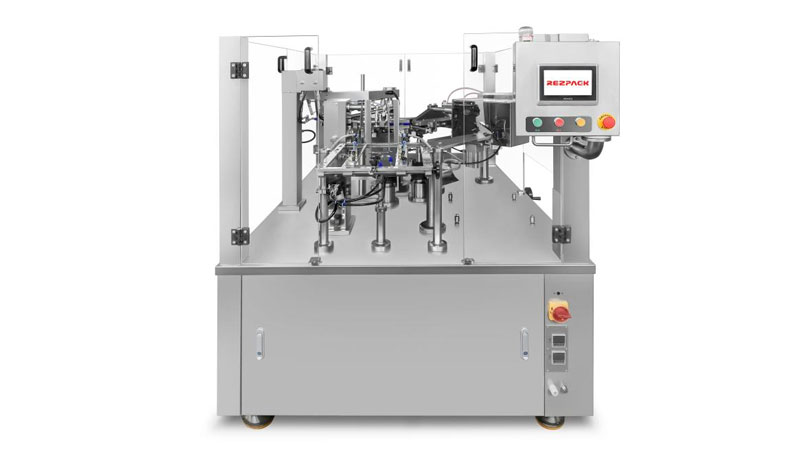

Rotary Packaging Machines: These machines have a circular design, with multiple stations arranged in a rotary format. They typically have a higher speed of operation compared to vertical packaging machines. Products move through different stages of packaging (filling, sealing, labeling, etc.) as the rotary mechanism rotates.

Vertical Packaging Machines: As the name suggests, these machines have a vertical design, where packaging operations occur in a linear or vertical manner. Products are fed vertically through the machine and undergo various packaging processes sequentially.

2.Speed and Efficiency:

Rotary Packaging Machines: Due to their continuous rotary motion and high number of stations, rotary machines are often faster and more efficient, making them suitable for high-volume production.

Vertical Packaging Machines: Vertical machines are still capable of high-speed packaging. They are particularly suitable for smaller batch sizes and diverse product types.

3.Versatility:

Rotary Packaging Machines: They are known for their versatility. They can handle a wide range of product types and packaging formats with minimal adjustments, making them suitable for industries with diverse product lines.

Vertical Packaging Machines: These machines are often designed for specific types of products or packaging formats. They may require more tooling changes to accommodate different products or package sizes.

4.Footprint and Space Requirements:

Rotary Packaging Machines: These machines typically have a larger footprint due to their circular design and multiple stations. They may require more floor space compared to vertical machines.

Vertical Packaging Machines: Vertical machines have a more compact footprint, making them suitable for facilities with limited space.

5.Packaging Types:

Rotary Packaging Machines: They are often used for premade products such as flat pouch,stand pouch,spout pouch,Lrregular-shaped Pouch,Gusset Pouch and zipper pouch.

Vertical Packaging Machines: These machines are commonly used for single-layer polyethylene, polyethylene composite materials, polypropylene composite materials, aluminum foil and other multi-layer composite films.

In summary, the choice between rotary and vertical packaging machines depends on factors such as production volume, product type, packaging format, floor space availability, and budget constraints. Both types of machines have their advantages and are suitable for different applications within the packaging industry.

| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

| Bag Width Range | 180-300 mm | Weight | 1800 kg |

| Bag Length Range | 150-450 mm | Total power | 3.62 kw |

| Filling weight | ≤ 2500 g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 50 bags/min | Dimensions | 2080 mm*1720 mm*1650mm |

| Bag Width Range | 270-400 mm | Weight | 2500 kg |

| Bag Length Range | 150-600 mm | Total power | 3.62 kw |

| Filling Range | ≤ 5000g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 30 bags/min | Dimensions | 2150 mm*2020 mm*1700 mm |