If you want to use roll film packing, we have VFFS machine, thermoforming type machine, horizontal packing machine for your choice.

Inquire NowIf you want to use roll film packing, we have VFFS machine, thermoforming type machine, horizontal packing machine for your choice.

Inquire Now

The packaging industry has undergone a transformative shift in recent years, driven by automation, sustainability, and precision engineering. From food and pharmaceuticals to consumer goods, advanced machinery like horizontal flow wrappers, vertical form fill seal machines, and automated carton packing systems are redefining efficiency and scalability. Here’s a closer look at the technologies powering this revolution.

A horizontal flow wrapper is a cornerstone of high-speed packaging lines, ideal for wrapping individual products such as candy bars, biscuits, or medical devices. This machine uses a continuous film to encase items horizontally, sealing the ends with precision. Modern versions integrate adjustable heat controls and compatibility with biodegradable films, aligning with eco-friendly packaging trends.

The vertical form fill seal machine is a marvel of automation. It creates bags from scratch by forming a roll of film into a pouch, filling it with product (like grains, powders, or liquids), and sealing it—all in one vertical motion. Its compact design minimizes floor space, while advanced sensors ensure consistent portioning and reduced material waste, making it a staple in food and pharmaceutical industries.

Unlike traditional form-fill-seal systems, a premade pouch machine handles pre-manufactured pouches (e.g., stand-up bags, spouted pouches). Equipped with robotic arms and vision systems, it swiftly fills and seals these ready-to-use pouches, perfect for brands prioritizing eye-catching, customizable packaging for snacks, beverages, or cosmetics.

The broader category of form fill and seal machines includes both vertical and horizontal systems. These machines adapt to diverse product shapes and sizes, offering flexibility for industries requiring frequent packaging changes. For example, a horizontal wrapper might handle bulky items like books or hardware, while a vertical variant focuses on granular products.

Completing the packaging line, an automated carton packing machine efficiently loads finished products into cartons, seals boxes, and prepares them for palletizing. This technology is critical for e-commerce and bulk manufacturing, reducing labor costs and ensuring secure transit. Some systems even integrate AI to optimize box sizes, cutting down on wasted space and materials.

The shift toward automated packaging machinery isn’t just about speed—it’s about sustainability and precision. IoT-enabled devices allow real-time monitoring of energy use and predictive maintenance, while AI-driven systems minimize errors. For instance, a vertical form fill seal machine can adjust sealing temperatures dynamically to prevent film tears, and a horizontal flow wrapper might recalibrate film tension based on product dimensions.

As demand for sustainable packaging grows, REZPACK machinery manufacturers are innovating with energy-efficient motors, recyclable materials, and modular designs. Hybrid systems that combine premade pouch filling with automated carton packing are also emerging, enabling end-to-end solutions for complex supply chains.

Whether it’s a high-speed horizontal flow wrapper for snack production or a vertical form fill seal machine for pharmaceuticals, these technologies underscore a universal truth: the future of packaging lies in smarter machines that do more with less—less waste, less energy, and less room for error.

Packaging plays a vital role in product protection, shelf life, and brand presentation. The two most common packaging machines used by the industry are the Vertical Form and Seal Machine (VFFS) and the Horizontal Form and Seal Machine (HFFS). While both automate the packaging process, they differ in design, functionality, and applications.

This article explores the differences between Vertical Form and Seal Machine and Horizontal Form and Seal Machine, focusing on Vertical Form and Seal Machine, its benefits, and how it compares to horizontal form and seal machines.

A Vertical Form and Seal Machine is a packaging system that forms a roll of film into a bag in a continuous vertical motion, then fills the bag with the product and seals it. These machines are widely used for packaging:

Snacks (chips, nuts, candies)

Granular products (powders, grains, seeds)

Liquids (sauces, beverages)

Pharmaceuticals (pills, capsules)

Space saving – vertical operation, takes up less space.

High speed packaging – suitable for small and medium-sized products.

Various packaging styles – pillow bags, gusseted bags or stand-up bags can be produced.

Reduce material waste – use pre-rolled film to reduce excess packaging.

Horizontal form-fill-seal machine can form bags or trays horizontally for larger or irregularly shaped products. Common applications include:

Frozen foods (pizza, vegetables)

Bakery goods (bread, cookies)

Medical devices (syringes, test kits)

Non-food items (toys, hardware)

Better for larger products – more efficient handling of larger or rigid items.

Tray sealing capability – can form rigid or semi-rigid packaging.

Higher production capacity – typically used in high-volume packaging lines.

III. Vertical vs. Horizontal Sealers: Key Differences

| Features | Vertical Form Fill Seal (VFFS) Machines | Horizontal Form Fill Seal (HFFS) Machines |

| Direction | Vertical operation (top to bottom) | Horizontal operation (side to side) |

| Best suited for | Small, granular, or liquid products | Large, bulky, or irregularly shaped items |

| Packaging Type | Pillow bags, stand-up pouches | Trays, flow bags, pouches |

| Space Requirements | Compact, for limited spaces | Requires more floor space |

| Speed | High speed, for small items | Slower speed, but can handle larger products |

| Flexibility | Better for lightweight products | Better for heavy or rigid packaging |

Vertical or horizontal sealer depends on your product type, production speed and packaging requirements.

For powders, granules or liquids (e.g., coffee, snacks, detergents)

Limited space in production facilities

High-speed, cost-effective packaging

For large or oddly shaped items (e.g., frozen foods, medical devices)

Need rigid or tray packaging

Large-volume production of larger products

After 32 years of intensive cultivation in the packaging industry, Ruizhi has developed and produced a variety of packaging machines for a variety of applications and has close ties with the international market. The brand's equipment is exported to more than 40 countries and serves more than 3,000 domestic and foreign companies. Ruizhi has partners in Southeast Asia, Europe and the United States, including internationally renowned brands such as Nestlé, Arvato, Hershey, and Colgate.

We are well aware that different companies have different needs and adopt customized solutions. We can also select the right equipment for you according to your needs and create professional equipment for your production.

Vertical full-cap sealers and horizontal cap sealers each have their own unique advantages depending on the specific application. Vertical fill-and-seal machine are ideal for small, granular or liquid products, and their compact design combines speed and efficiency. Horizontal fill-and-seal machine, on the other hand, are more suitable for larger items that require tray or pillow packaging.

By understanding the differences between these two packaging systems, companies can choose the right machine to optimize efficiency, reduce waste, and improve product appearance.

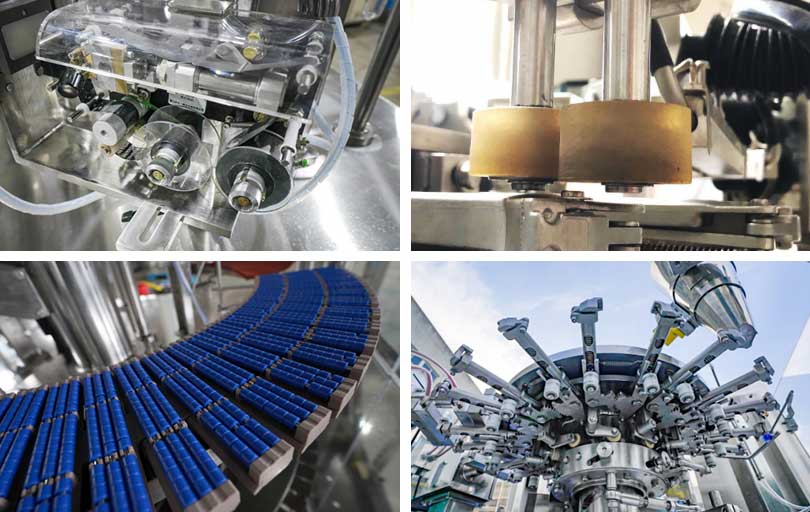

Form, Fill and Seal (FFS) machinery represents one of the most significant advances in modern packaging technology. These automated systems have revolutionized production lines in the food, pharmaceutical and consumer goods industries by merging three critical packaging steps into one seamless operation. FFS machines create packages from flexible materials, fill them with precise amounts of product, and seal them with minimal human intervention and maximum efficiency.

Three-Step Process

1. Forming: The machine forms a web (plastic film, laminate or other flexible material) into the desired shape, whether it is a bag, packet or other container.

2. Filling: Dispensing a precisely measured amount of product into the newly formed package.

3. Sealing: Using heat, pressure or other methods, the filled package is sealed to ensure product protection and extended shelf life.

Types of FFS Machines

Vertical Form Fill Seal (VFFS) Machines:

For granular products, liquids and powders.

The package is formed vertically and the product is filled by gravity or a pump.

Commonly used for snacks, coffee, frozen foods and pharmaceuticals.

Horizontal Pouch Packaging Machines:

Best for solid products or items that need to be placed horizontally.

Commonly used for preformed pouches, stick packs and blister packs.

Commonly used for confectionery, medical devices and single-serving condiments.

Thermoform Fill Seal Machines:

Use heated dies to form plastic sheets into rigid or semi-rigid packages that are then filled and sealed. Commonly used in medical packaging and premium foods.

Key Benefits of FFS Machinery

Operational Efficiency

Vertical Form Fill Seal Machines Allow for high production speeds (up to hundreds of packages per minute).

Horizontal Pouch Packaging Machines Allow for precise product placement and less waste.Both types minimize labor costs and improve consistency.

Product Protection

Sealing ensures extended shelf life.

Excellent barrier properties (moisture, oxygen, light).

Reduced risk of contamination compared to manual packaging.

Flexibility and customization

VFFS machines allow for quick changeover to different bag sizes.

Horizontal bagging machines support pre-made bags with zipper, spout or stand-up function.

Both can be integrated with smart sensors and Industry 4.0 technologies.

Cross-industry applications

Food and beverages

VFFS machines: chips, nuts, powdered beverages.

Horizontal bagging machines: candy bars, sauce packets, tea bags.

Pharmaceutical and medical

VFFS machines: pill packets, sterile medical supplies.

Horizontal bagging machines: blister packs, diagnostic test kits.

Choosing the right FFS machine

Choosing between Vertical Form Fill Seal and Horizontal Pouch Packaging Machine

| Factors | VFFS Machine | Horizontal Pouch Packaging Machine |

| Best suited | Granules, powders, liquids | Solids, pre-made bags |

| Speed | Very high (200+ bags/minute) | Medium to high |

| Flexibility | Fast size changes | Suitable for custom shapes |

| Cost | Lower unit cost | Higher initial investment |

Customized packaging solutions

REZPACK,After 32 years of deep cultivation in the packaging industry, close communication with the international market, exporting to more than 40 countries, and serving more than 3,000 domestic and foreign companies, ruizhi has partners in Southeast Asia, Europe, and the United States. These include various internationally renowned brands such as Nestle, Oweilin, Hershey, Kao, etc.

Knowing that different companies have different needs, we adopt customized solutions. We can select the right equipment for you according to your needs and create professional equipment for your production.

Whether you need a vertical form fill seal machine for high-speed granular packaging or a horizontal bag packaging machine for precision filling solid products, FFS technology provides unparalleled efficiency and versatility. Investing in the right system can improve product quality, reduce waste and increase profitability in a competitive market.

In the fast-paced world of manufacturing and packaging, efficiency, precision, and reliability are essential. One of the most innovative solutions to emerge in recent years is the Pick-Fill-Seal Machine for Preformed Bags. This advanced equipment has changed the way the industry approaches packaging, especially preformed bags. In this article, we will explore what this machine is, how it works, its key features, and the benefits it brings to various industries.

The Pick-Fill-Seal Machine for Preformed Bags is a state-of-the-art packaging system designed to automate the process of picking, filling, and sealing preformed bags to create efficient sealed packaging. Unlike traditional form-fill-seal machines that use roll stock to make bags, this machine is specifically designed to work with preformed bags, providing greater flexibility and efficiency for certain applications.

The machine is ideal for industries that require high-speed, high-precision packaging, such as food and beverage, pharmaceuticals, pet food, and personal care products. Its ability to handle a wide range of bag sizes, shapes, and materials makes it a versatile solution for a variety of packaging needs.

How does a pre-made bag pick-fill-seal machine work?

A rotary Premade Pouch Pick Fill Seal Machine operates through a series of highly coordinated steps:

1. Bag Picking: The machine picks up the pre-made bag from a stack or magazine using a robotic arm or suction system. This ensures precise handling and minimizes the risk of bag damage.

2. Bag Opening: After picking up the bag, the machine opens it using a combination of robotic fingers. This step is critical to ensure the bag is ready for filling.

3. Product Filling: The opened bag is then moved to a filling station where the product is dispensed with high precision. The machine can handle a wide range of products including liquids, powders, granules and solids.

4. Bag Sealing: After filling, the bag is transferred to a sealing station where it is sealed using heat, pressure technology, depending on the bag material and product requirements.

5. Discharge: The sealed bag is then discharged onto a conveyor or collection bin ready for further processing or packaging.

1. High-speed operation: The machine can process hundreds of bags per minute, greatly improving production efficiency.

2. Versatility: It can handle various types of bags, including stand-up pouches, flat bags, spouted bags, etc. It also supports a variety of materials, such as plastic, foil, and biodegradable films.

3. Precision filling: The advanced batching system ensures accurate filling, reduces product waste, and ensures consistent packaging weight.

4. User-friendly interface: The machine is equipped with an intuitive touch screen interface for easy operation and adjustment of settings.

5. Hygienic design: Made of food-grade materials, the machine is easy to clean and meets strict hygiene standards, suitable for food and pharmaceutical applications.

6. Customization options: The machine can be customized to specific production requirements, including bag size, filling volume, and sealing method.

1. Increased productivity: By automating the packaging process, the machine significantly reduces labor costs and increases output.

2. Improved product quality: Precise filling and sealing ensures consistent and safe product packaging, maintaining its quality and shelf life.

3. Reduced waste: Accurate dosing and minimal product spillage help reduce material and product waste.

4. Flexibility: The ability to handle different bag types and sizes allows manufacturers to quickly adapt to changing market demands.

5. Cost-effectiveness: While the initial investment may be significant, the long-term savings in labor, materials, and increased production efficiency make it a cost-effective solution.

Rotar pre-made bag pick-fill-seal machines are widely used in various industries, (Click to get the solution):

Food and beverage: For packaging snacks, sauces, beverages, and ready-to-eat foods.

Pharmaceuticals: For packaging powders, tablets, and liquid medications.

Pet food: For packaging dry and wet pet food.

Personal care: For packaging shampoos, lotions, and other cosmetics.

With over 33 years of experience in the packaging industry and 20 years of focus on rotary packaging machines, Rezpack has over 3,000 customers in Europe, the United States, Australia and Asia who trust Rezpack machines to meet their packaging needs

Our rotary pre-made bag pick fill seal machines can be tailored to your product and packaging requirements. Whether you are packaging granules, powders or liquids, our machines can handle a wide range of bag types, including stand-up bags, zipper bags, spout bags and shaped bags. We will provide a customized solution within 24 hours, taking into account your product characteristics, bag type, size and weight.

We have successfully implemented packaging solutions for a variety of products, including cereals, coffee, nuts, jerky, tea, potato chips, flour, spices, water, oil and detergents. Our rotary packaging machines support a variety of packaging bag sizes, which can be easily adjusted through the touch screen, and the settings can be saved for future use. If you are still struggling to choose the right machine, our technicians will provide you with the best solution.

GET A QUOTE