Description

The core of RZ8-S95-12ZK high-speed rotary vacuum packaging machine

At the heart of theRZ8-S95-12ZK High Speed Rotary Vacuum Packaging Machine is a powerful vacuum system that can create a vacuum effect of up to 2mbar, ensuring that products are fully sealed and protected from air and moisture. With 12 vacuum chambers, this machine is capable of processing large volumes of products quickly and efficiently, making it a popular choice for manufacturers and processors in a variety of industries.

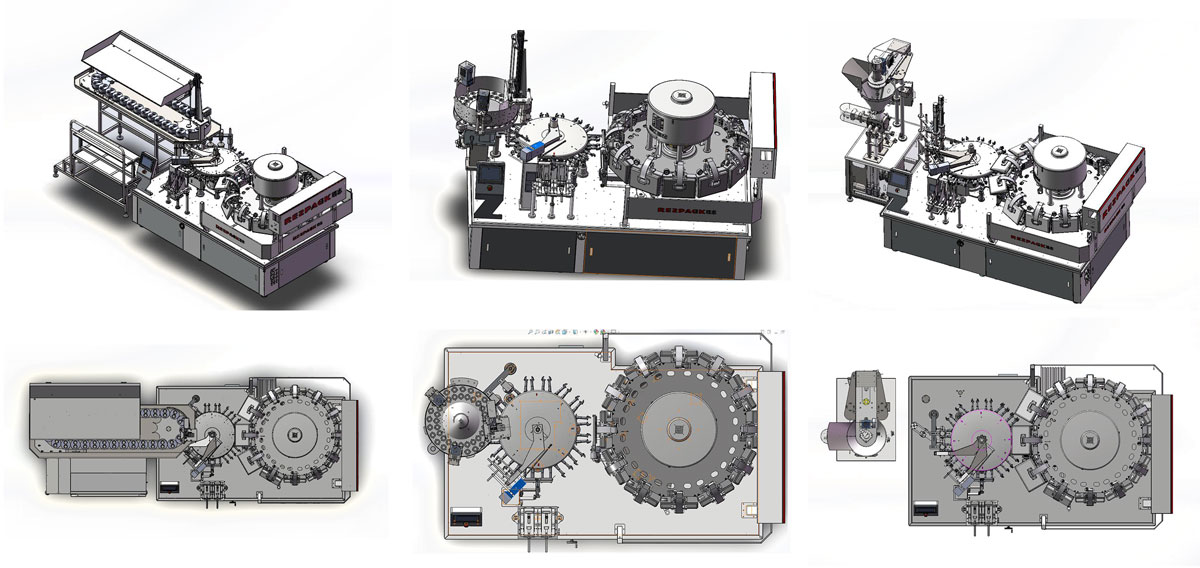

Advantages of RZ8-S95-12ZK high speed rotary vacuum packaging machine

One of the key advantages of the RZ8-S95-12ZK High Speed Rotary Vacuum Packaging Machine is its ease of use and maintenance. The machine features a user-friendly touch screen interface that allows operators to easily control and adjust settings to meet their specific needs. The bag feeding mechanism is also optimized for improved performance and convenience, with a double fulcrum arm design that eliminates the need for a timing belt and ensures a stable, reliable feed.

Other advanced features of the RZ8-S95-12ZK High Speed Rotary Vacuum Packaging Machine include an automatic oil lubrication system that keeps the machine running smoothly and efficiently, as well as an independent closing function for each vacuum chamber that allows the machine to continue operating even if one of the chambers is malfunctioning. These improvements make the RZ8-S95-12ZK High Speed Rotary Vacuum Packaging Machine a durable and reliable choice for businesses seeking consistent, high-quality vacuum packaging.

Overall, the RZ8-S95-12ZK High Speed Rotary Vacuum Packaging Machine is a top-of-the-line choice for businesses looking to streamline their packaging operations and improve product quality. With its advanced features, ease of use, and reliable performance, this machine is a valuable investment for businesses in a wide range of industries, from food and beverage to pharmaceuticals and beyond.

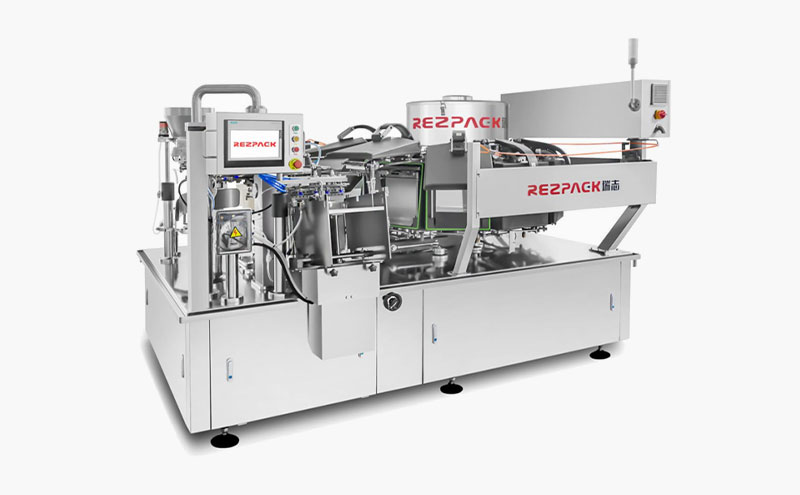

Unloader

Can be used with commonly used ancillary products such as ring feeder/measuring cup feeder/shrink cup/servo filling machine/electronic scale/screw scale

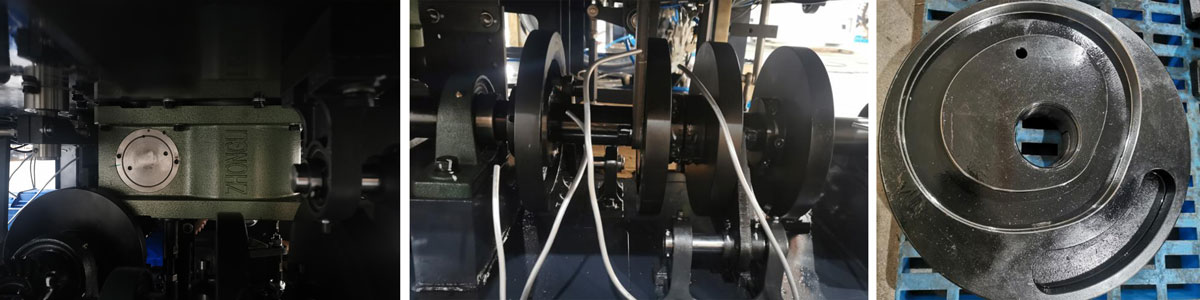

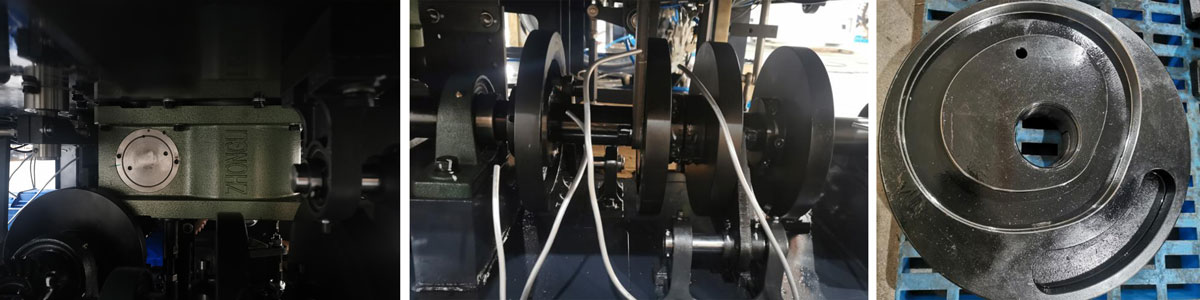

Three major spine components (Lifetime warranty)

1---Continue to use the top-mounted divider, which has high installation fit, low risk of pitting corrosion, low wear, and low maintenance difficulty.

(Peer type box type cylindrical cam indexing box)

2---air distribution plate

3---Cam

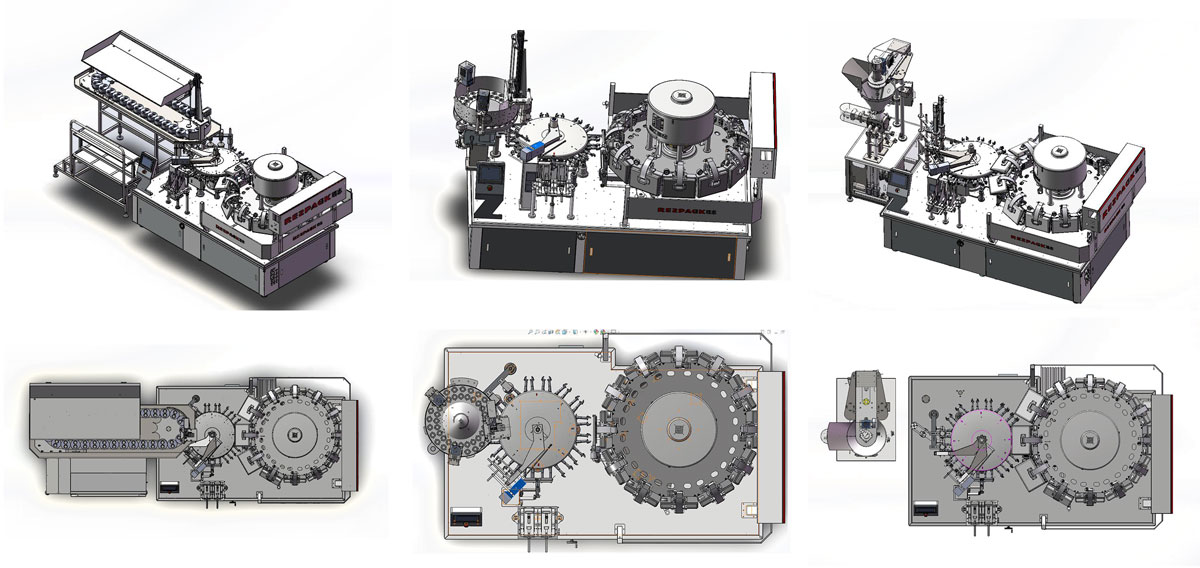

Craftsmanship

1---Rack

The frame is assembled through rough milling, welding, annealing, CNC finishing, and assembly. Ordinary frames are only leveled, rough milled, and then welded.

The rack plate is twice as thick as an ordinary rack, and the rack only weighs 1.3 tons.

Multiple processes and high-precision machining are fully guaranteed and run smoothly at a mechanical speed of up to 80 times per minute.

The rack structure is optimized, the layout is more scientific and reasonable, and installation and maintenance are more convenient.

2---Transmission

The transmission has been changed from a cumbersome concave-shaped layout to a simple T-shaped layout, eliminating multiple pairs of transmission gears, making the transmission efficiency higher, more stable and reliable. Professionally customized interval indexers can withstand high torques of 75 times per minute. The interior adopts a curved indexing mechanism, an enlarged indexing plate, direct connection to the output, and a sealed box structure. It has good rigidity, strong load-bearing capacity, stable operation and high precision. Immersion lubrication makes high-speed operation more reliable and has a longer service life. All cams are designed and manufactured from the ground up to optimize speeds of 150 beats per minute. The cam disc is larger and the cam curve is smoother after optimization. It is manufactured using high-quality 20CrMnTi through multiple processes. All use grooved cams to avoid defects such as jump of the outer cam under high-speed operation, vibration, and fatigue fracture of the tension spring.

3---Bag carousel

The original high-speed bag feeding turntable adopts an 8-station design. More stations provide more packaging process requirements at high speed. The reinforced turntable seat, turntable bushing, etc. are made of 304 stainless steel, which greatly improves the anti-corrosion performance. Improved, the central rotating shaft is made of imported special steel and processed as a whole (ordinary machines use 45 steel welded flange and then processed). Whether it is bag loading, bag opening or bag opening, they are designed and manufactured at a speed of 75 times per minute. The bag support does not require any slots or rollers, it only relies on cam drive, and is still stable without shaking at a speed of 75 times per minute.

4---Vacuum turntable

The vacuum turntable bearing seat, bearings and turntable are all redesigned and manufactured, and the rigidity and strength are more than twice that of ordinary models. The vacuum chamber uses a 12-station design and is equipped with an original vacuum and sealing control system, making it more flexible and convenient to adjust according to the performance status of the material. The vacuum chamber is made of high-quality aviation aluminum, with reliable sealing and beautiful appearance, and does not need to be covered with any decorative panels.

5---Others

The automatic circulating oil lubrication system continuously injects oil directly into the parts that need lubrication instead of spraying it on the surface. Vacuum pipes, air pipes, water pipes, etc. can be connected in different directions according to the layout of the customer's workshop. The independent electrical box is laid out in a scientific and reasonable manner, without any messy pipelines, and is sealed without redundant openings to prevent foreign matter from entering. Compared with a single-pack vacuum machine with the same production efficiency, a double-pack vacuum machine can save 30%-40% of the production site area, operators, equipment energy consumption, and cleaning time; the stability of the equipment operation Improved by 1.2-1.5 times. Compared with the single-pack vacuum machine, the double-pack vacuum machine not only increases the packaging speed, but also reduces the operating speed of the equipment host. The equipment runs more stably, has less wear, and the service life of equipment-related parts is extended to 1.5-2 times the original.