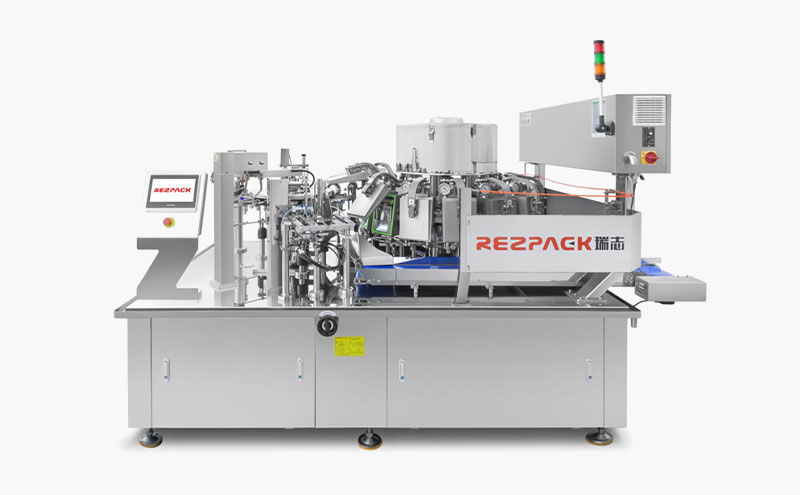

Sachet Form Fill Seal (FFS) machines are designed for high-efficiency packaging of small, portion-sized products, providing both flexibility and accuracy in production. This packaging style is widely used for products that require controlled portions, extended freshness, and a sleek presentation.

What is Sachet Form Fill Seal Packaging?

Sachet Form Fill Seal machines create, fill, and seal sachets or small pouches in one seamless process. These sachets are often used for tea, coffee, spices, powders, granules, and liquid products, ensuring accurate dosing and maintaining product freshness.

Rezpack’s Sachet FFS Machines offer cutting-edge technology to create high-quality packaging solutions, including specialized designs such as three-dimensional pyramid tea bags, which enhance functionality and appeal.

Key Features of Sachet Form Fill Seal Machines

1.Versatility in Sachet Design

●Supports various sachet styles such as flat sachets or three-dimensional pyramid tea bags.

●Suitable for powders, liquids, granules, and even delicate products like tea leaves.

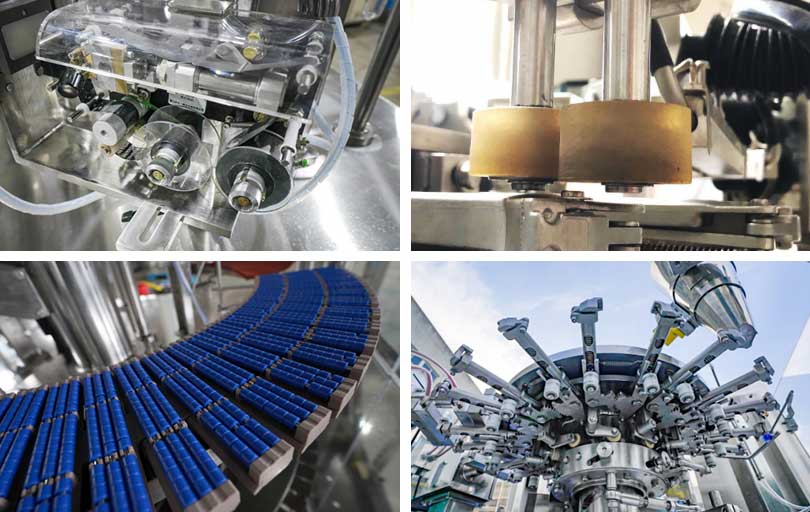

2.Precision Filling Systems

●Equipped with auger fillers, volumetric fillers, or liquid pumps for precise dosing.

●Ensures consistency in weight and minimizes material waste.

3.High-Speed Performance

●Capable of producing up to 120 sachets per minute, ideal for high-volume production lines.

●Stable operation with minimal downtime.

4.Hygienic and Food-Safe Construction

●Constructed with SUS304 stainless steel, compliant with GMP standards.

●Easy-to-clean design ensures sanitation and safety.

5.Advanced Sealing Technology

●Airtight sealing to maintain freshness and aroma.

●Special sealing for pyramid sachets ensures durability and aesthetics.

6.Customizable Options

●Options for tag and string attachment for tea sachets.

7.User-Friendly Operation

●Intuitive HMI touch screen control for easy parameter adjustment.

●Minimal setup time for different sachet sizes and products.

Applications of Sachet Form Fill Seal Machines

Sachet FFS machines are ideal for a wide range of industries, including:

●Tea & Coffee: Pyramid tea bags, instant coffee sachets.

●Spices & Seasonings: Sugar, salt, pepper, powdered seasonings.

●Pharmaceuticals: Single-dose medicines or supplements.

●Liquid Products: Shampoo, lotion, sauces, or juices.

Case Study: Pyramid Tea Bags

Rezpack’s Sachet FFS Machine recently demonstrated its capabilities by packaging pyramid tea bags for a premium tea brand.

●Product: Loose tea leaves and flowers.

●Packaging Style: Transparent triangular sachets with a string and tag.

●Features:

●Gentle filling to prevent leaf breakage.

●Airtight sealing to preserve aroma and freshness.

●High-speed operation, producing 60 pyramid bags per minute.

The pyramid shape not only provided an elegant appearance but also allowed the tea to steep more effectively, enhancing the customer’s brewing experience.

Advantages of Sachet Form Fill Seal Packaging

1.Cost-Effective Production

●Automates the entire process, reducing labor costs.

●Precise filling minimizes product waste.

2.Enhanced Product Presentation

●Unique sachet designs like pyramid tea bags stand out on the shelf.

●Transparent materials allow customers to see the product quality.

3.Improved Shelf Life

●Airtight sealing and optional nitrogen flushing protect product freshness.

4.Sustainability

●Compatible with eco-friendly packaging materials for a greener footprint.

5.Convenience for End Users

●Single-use sachets offer portability and controlled portions.

Conclusion

Sachet Form Fill Seal Machines are the ultimate solution for creating high-quality, convenient, and visually appealing packaging. Rezpack’s advanced technology ensures precision, efficiency, and reliability, making these machines ideal for businesses aiming to elevate their product packaging.

From pyramid tea bags to single-serve sachets, Rezpack delivers innovative solutions to meet the unique needs of your industry.

Transform your packaging process with Sachet Form Fill Seal Machines today!

Inquire Now