Big Bag Packing is designed for industries that require high-capacity, precision, and durability in their packaging processes. This packaging method is particularly suitable for large quantities of products, ensuring optimal efficiency and cost-effectiveness.

What is Big Bag Packing?

Big Bag Packing involves filling and sealing large pouches or bags, typically for bulk products or oversized packaging needs. This solution is ideal for industries such as food, agriculture, chemicals, and pet care, where handling large volumes is essential.

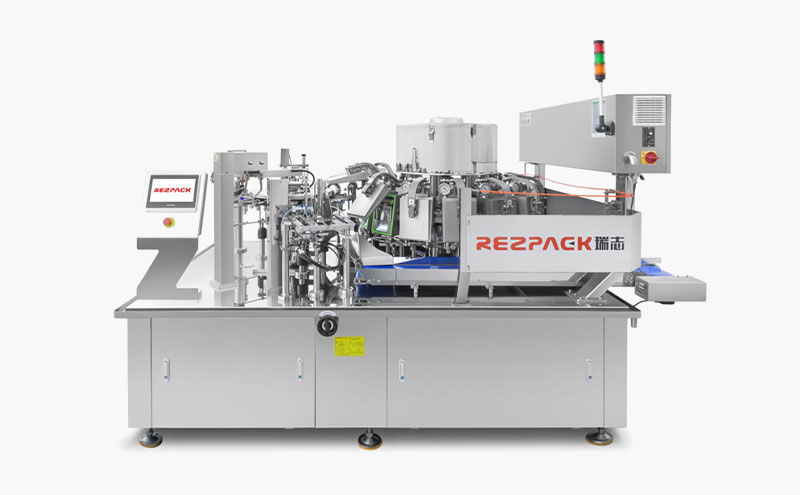

Rezpack’s Big Bag Packing Machines offer state-of-the-art technology, combining precision, reliability, and automation to streamline the packaging process.

Key Features of Big Bag Packing Machines

1.High-Capacity Solutions

●Capable of handling bag volumes ranging from 1 kg to 10 kg or more.

●Designed to accommodate diverse product types, including powders, granules, and semi-liquids.

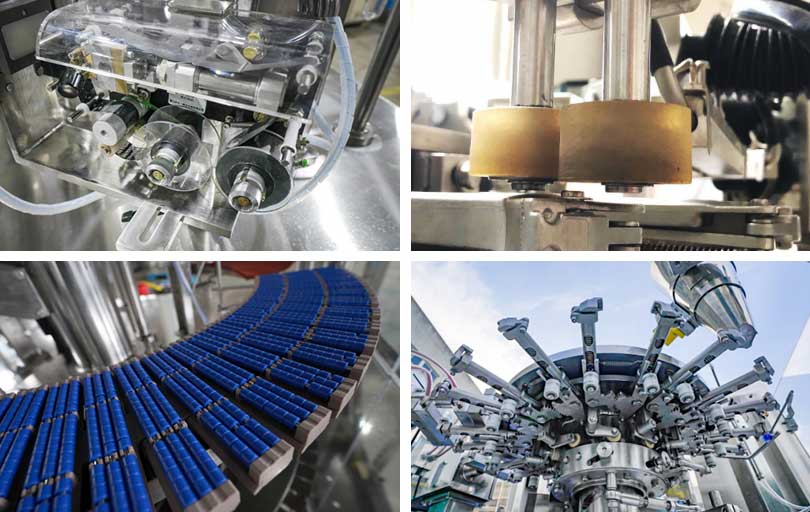

2.Advanced Weighing and Filling Systems

●Equipped with multi-head weighers, screw fillers, or auger conveyors to ensure precise measurements.

●Customizable filling speeds to match specific production requirements.

3.Durable and Reliable Design

●Constructed with SUS304 stainless steel for enhanced durability and sanitation.

●Rugged design ensures long-term performance even in demanding industrial environments.

4.Versatility for Bag Types

●Compatible with different bag styles, including pre-made pouches, gusseted bags, and zipper bags.

●Suitable for a wide range of materials, from kraft paper to laminated films.

5.Automation and Ease of Use

●Intuitive PLC touch screen control for easy operation and parameter adjustment.

●Automated processes for bag feeding, filling, sealing, and output reduce labor requirements.

6.Enhanced Sealing Quality

●Perfect sealing to maintain product integrity, prevent spillage, and extend shelf life.

Applications of Big Bag Packing

Big Bag Packing is ideal for industries with bulk product requirements, such as:

●Food and Beverages: Flour, rice, sugar, coffee beans, grains.

●Agriculture: Fertilizers, seeds, animal feed.

●Chemicals: Powdered chemicals, plastic granules, detergents.

●Pet Care: Pet food, litter.

Case Study: Big Bag Packing for Animal Feed

Rezpack’s Big Bag Packing Machine was recently employed for a leading animal feed manufacturer. The machine featured:

●Automated feeding and filling systems for precision.

●Dust-proof sealing to ensure cleanliness and safety.

●High-speed production that allowed 30 bags per minute, significantly boosting output efficiency.

The system not only minimized material waste but also ensured the durability and integrity of each bag, meeting the customer’s high standards.

Advantages of Big Bag Packing

1.Cost Efficiency

●Reduces labor costs through automation.

●Minimizes material wastage with precise filling systems.

2.Increased Productivity

●Handles bulk packaging requirements efficiently.

●High-speed capabilities allow faster turnaround times.

3.Versatility

●Adaptable to a wide range of industries and product types.

●Compatible with different bag styles and materials.

4.Improved Product Quality

●Airtight sealing ensures product freshness and prevents contamination.

●Durable bags protect products during storage and transportation.

Conclusion

Big Bag Packing is an essential solution for businesses managing high-volume production and bulk product packaging. With Rezpack’s advanced technology and customizable designs, our Big Bag Packing Machines deliver exceptional performance, reliability, and efficiency.

Whether you’re packaging grains, chemicals, or pet food, Rezpack provides the tools to meet your industrial packaging needs while ensuring quality and cost-effectiveness.

Choose Big Bag Packing to maximize your production efficiency and product quality today!

Inquire Now