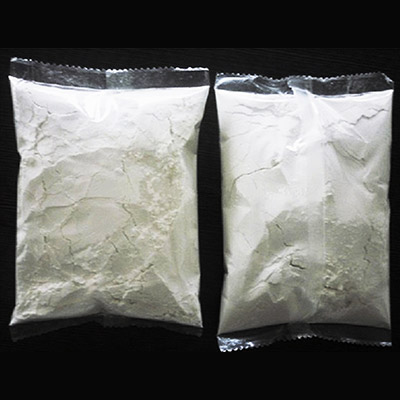

Efficient Powder Packaging for Precision and Cleanliness

At UNIONPACK, we provide advanced powder packaging equipment designed to maximize efficiency, accuracy, and safety in your production line. Our machines include rotary premade pouch packaging machines, Vertical Form Fill Seal Machine and Horizontal Flow Wrapper, and cup filling sealing machines—each tailored for seamless powder handling. Equipped with auger conveyors, vacuum feeders, auger fillers, and dust control systems, our solutions meet the specific needs of powder packaging with precision.

Why Choose UNIONPACK for Powder Packaging?

1. Consistent Flow and Precision

Our auger conveyors are engineered for steady, accurate material flow, ideal for powders such as flour, sugar, spices, and more. Paired with auger fillers, they deliver exact doses in every package, eliminating waste and ensuring consistency in product quantity.

2. Enhanced Cleanliness and Safety

To maintain a clean and safe work environment, our systems come with integrated dust collection and anti-dust devices. These prevent airborne particles and spills, protecting product quality while enhancing safety and ensuring compliance with industry standards.

3. Comprehensive Equipment Options

From rotary premade pouch pick fill seal machines to vertical form fill seal machines and horizontal pouch packaging machines, we offer solutions adaptable to various powder packaging requirements. Coupled with vacuum feeders, our equipment allows for efficient, hands-free material transfer to the filler, minimizing handling time and reducing contamination risks.

Advantages of UNIONPACK’s Powder Packaging Solutions

• Accurate Dosing: Auger fillers ensure precise measurements, maintaining product consistency.

• Efficient Dust Management: Dust collection systems reduce airborne particles, promoting a cleaner workspace.

• Versatile Machine Options: Our range supports different packaging formats, such as bags, pouches, and cups, for customized solutions.

UNIONPACK’s powder packaging equipment is designed to streamline production, protect product integrity, and improve efficiency. Contact us today to learn how our advanced machinery can transform your powder packaging processes