Standard 10 heads & 14 heads weighing

Special design for sticky products

Great accuracy to 0.5%

| Machine name | 4 Head Linear Weigher | Weighing Speed | 50bags/min |

| Model | RZKL -4 | Total power | 1KW |

| Max Load | 1000g | voltage | 220V single phase 50/60HZ |

| Weighing Accuracy | 0.5-1g | Weight | 220KGS |

| Packaging Range | 10~1800 cc | Power | 700W |

| Division Value | X0.1 | Voltage | 220V, 50/60Hz |

| Accuracy | 1/1000 F.S. 2σ | Cache Volume | About 75L |

| Speed | ≤ 80 bags/min | Total Weight | About 200kg |

| Weigh the bucket | 10 | Weighing volume | 3.0L |

| Speed | ≤80BPM | Weight | 260Kg |

| Accuracy | ±3σ | Monitor | 10.4 Color video touch screen |

| Single bucket volume | 1.6L | Power Supply | AC220V±10% 50/60Hz 1KW |

| Weigh the bucket | 14 | Weighing volume | 5.0L |

| Speed | ≤120BPM | Weight | 400kg |

| Accuracy | ±3σ | Size (L*W*H) | 1160 * 1160 * 1350 mm |

| Single bucket volume | 2.5L | Power Supply | AC220V±10% 50/60Hz 1.8 KW |

| Weigh the bucket | 14 | Weighing volume | 3.0L |

| Speed | ≤130BPM | Weight | 350Kg |

| Accuracy | ±3σ | Monitor | 10.4 Color video touch screen |

| Single bucket volume | 1.6L | Power Supply | AC220V±10% 50/60Hz 1.5KW |

| Weigh the bucket | 14 | Weighing volume | 1.5L |

| Speed | ≤90BPM | Weight | 400Kg |

| Accuracy | ±2σ | Monitor | 10.4 Color touch screen |

| Single bucket volume | 1L | Power Supply | AC220V±10% 50/60Hz 1.8KW |

| Packaging Range | 10~3000cc | Power Source | Single phase 220V, 50/60Hz |

| Division Value | X0.1 | Cache Volumn | around 40 L |

| Degree of Accuracy | 1/1000 F.S. 2σ | Total Weight | around 160 kg |

| Speed | ≤ 40 bags/min | Power | 500W |

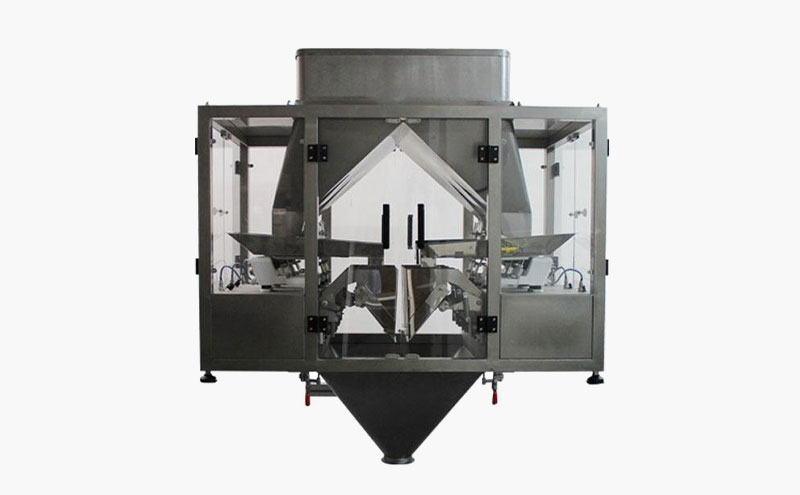

Our Multi-head Weigher is the ideal solution for achieving accurate and efficient weighing of various products. Designed to improve productivity and minimize waste, this state-of-the-art machine is a staple in industries such as food, pharmaceuticals, chemicals, and hardware.

With a standard configuration of 10 or 14 weighing heads, the Multi-head Weigher ensures exceptional accuracy, reaching precision levels as high as 0.5%. Its advanced design and robust technology make it the best choice for businesses that prioritize precision and speed in their packaging processes.

1. Superior Accuracy: Achieving precision up to 0.5%, the Multi-head Weigher ensures your products are consistently weighed to the desired specifications, minimizing product giveaway and maximizing profits.

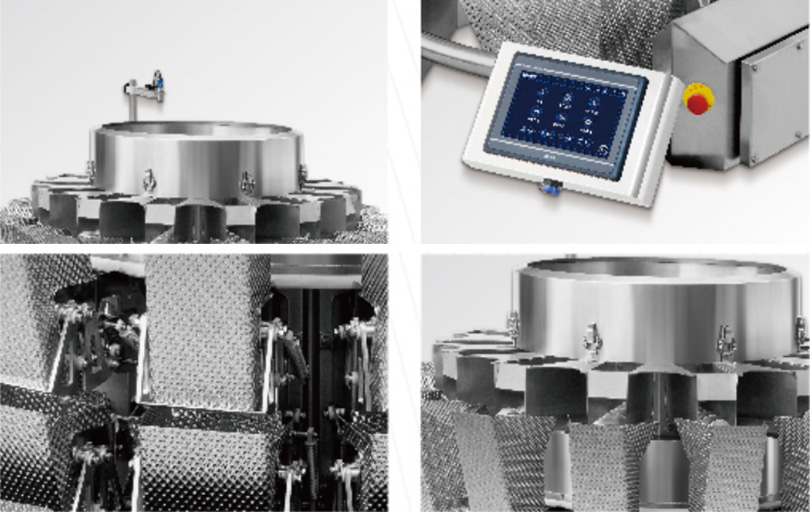

2. Advanced Technology: Equipped with digital signal processing, the weigher provides high-speed, stable performance, significantly reducing weighing errors and boosting your production efficiency.

3. Sticky Product Handling: This machine’s unique design effectively handles sticky or moist products like fresh produce, frozen foods, or dried fruits, ensuring smooth operation without disruptions.

4. User-Friendly Interface: The machine is designed for easy operation and maintenance, featuring an intuitive user interface that allows for quick adjustments and easy setup. This enables operators to efficiently run the machine with minimal training.

5. Self-Tuning Vibration System: The advanced vibration system optimizes product flow and reduces bottlenecks, ensuring faster weighing and packaging, further improving efficiency.

6. Quick Cleaning and Maintenance: With a tool-free cleaning system, the machine minimizes downtime between product changes, making it ideal for businesses handling multiple product types.

The Multi-head Weigher is suitable for a variety of product types across multiple industries:

* Snack Foods: Dried fruits, nuts, potato chips, and candy.

* Fresh Produce: Vegetables, fruits, and meats.

* Frozen Foods: Frozen vegetables, meats, dumplings, and seafood.

* Hardware & Plastics: Small plastic parts, screws, and nuts.

* Small Packaging: Tea bags, coffee bags, and powdered products.

* Increased Efficiency: Faster calculation times result in more packs per shift, helping you meet high production demands.

* Cost Savings: Improved weighing accuracy means more packs per kilogram of product, reducing waste and maximizing profitability.

* Flexibility: The machine offers a range of options and can be easily integrated with your existing production line, enhancing your overall operational flexibility.

GET A QUOTE