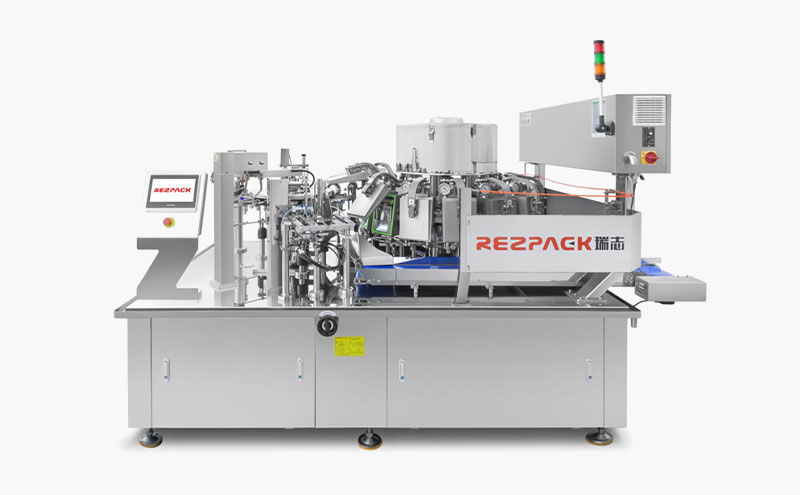

Established in 2009, REZPACK has become a trusted name in the packaging industry, specializing in the design and manufacturing of automatic cup filling machines and capsule filling solutions. Our commitment to innovation and high-performance technology has made us a preferred supplier in over 40 countries, catering to diverse industries such as food, beverage, and pharmaceuticals.

Tailored Capsule Filling & Sealing Solutions

At REZPACK, we understand the unique requirements of capsule filling and sealing for products such as coffee, powders, and other granular substances. Our K-cup filling machines are engineered to offer precision and efficiency, ensuring the highest quality standards. Ideal for coffee capsules, K-cups, and other similar packaging, our machines are designed to handle pre-cut aluminum foil or drawn films for a perfect seal.

Key Features of Our Capsule Filling Machines:

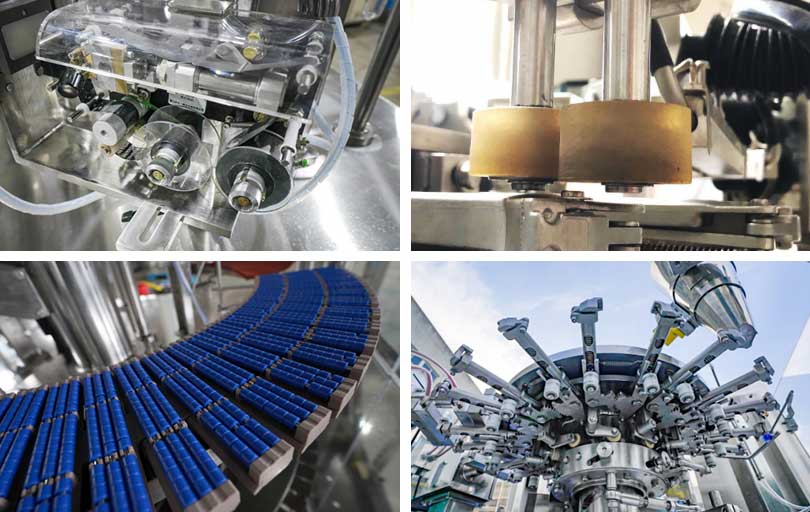

1.Servo-Driven Auger Filler: Our advanced servo-driven system ensures precise filling, with a weight difference of only ±0.15g. This guarantees high accuracy in every capsule, optimizing product quality and reducing waste.

2.Nitrogen Flush System: To extend the shelf life of your product, especially in the coffee industry, our machines include a nitrogen flush system. This system ensures that the nitrogen content inside each capsule reaches 96%, preserving the freshness and aroma of coffee powder and other sensitive products.

3.Flexible Capacity & Speed: Our machines can fill capsules at speeds ranging from 600 to 6,000 capsules per hour, with adjustable production speed through the variable frequency variable speed system. This adaptability makes our equipment ideal for both low and high-volume operations.

4.High-Quality Components: We use top-tier international brands for critical components such as Mitsubishi, Schneider, and Siemens for sensors, cylinders, solenoid valves, and frequency controllers. This ensures exceptional reliability and longevity.

5.Customization Options: Understanding that each client has specific needs, we offer fully customizable solutions to fit the product, container size, and packaging material of your choice (e.g., PP, PET, PS, paper, laminated films). We also provide expert consultation to help you optimize your production setup.

Why Choose REZPACK for Capsule Filling & Sealing?

●Precision and Efficiency: Our machines are designed for precision filling, with high-speed output and minimal errors.

●Advanced Technology: From servo-driven fillers to nitrogen flushing systems, our machines incorporate cutting-edge technology for maximum performance.

●Flexibility: Our machines can handle various product types and packaging materials, ensuring they meet the needs of diverse industries.

●Hygienic Design: With a focus on food-grade quality and hygienic standards, our machines are made of SUS 304 stainless steel, ensuring safety and durability.

●Complete Service: We provide full financing options, expert installation, and ongoing support to ensure your operations run smoothly.

Whether you are packaging coffee, powders, or granular substances, REZPACK’s capsule filling and sealing solutions deliver optimal performance and reliability. Contact us today to discuss your packaging needs, and let us customize a solution tailored to your business.

Inquire Now