| Capacity | 10-20 capsules/m | Air Supply | ≥0.6Mpa |

| Filling Accuracy | ±1% | Weight | 200 Kg |

| Capacity | 10-20 capsules/m | Air Supply | ≥0.6Mpa |

| Filling Accuracy | ±1% | Weight | 200 Kg |

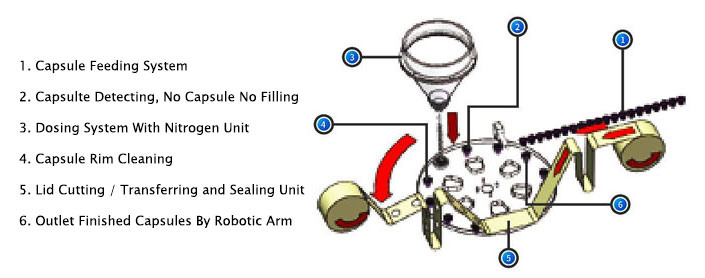

The Linear Capsule Filling and Sealing Machine is a state-of-the-art equipment designed for efficient and reliable capsule filling and sealing. Developed by our team of experts, this machine boasts several unique features that set it apart from the competition.

Firstly, the machine features a large, self-developed cup storage compartment that can hold a significant amount of empty capsules. This allows for automatic cup feeding, reducing the need for manual labor and significantly cutting down on production costs.

The precise metering method employed by the machine ensures that every product filling is accurate and consistent. Additionally, the product pressure filling and the cup's edge dust removal device provide a double guarantee that the cup is 100% clean.

The machine's easy-to-dismantle and clean design allows for quick and convenient product changes, even between different types and sizes. Furthermore, the adjustable design allows the use of various cup types and sizes, making it versatile and adaptable to different product requirements.

The Linear Capsule Filling and Sealing Machine enables the addition of liquid and solid flavorings to the cups, enhancing product variety and appeal. Moreover, it operates quietly, consumes minimal air, and runs on a fully servo system, minimizing maintenance requirements.

In summary, the Linear Capsule Filling and Sealing Machine is a reliable and efficient solution for capsule filling and sealing needs. Its innovative features and versatile design make it an excellent investment for businesses seeking to streamline their production processes while reducing costs and increasing product diversity.

| Models | UN-20KJBZ | UN-50KJBZ | UN-100KJBZ | UN-200KJBZ | UN-400KJBZ |

| Parts Contact With Product | Foodsafe Stainless Steel AISI 304 | ||||

| Capacity | 10-20 capsules/m | 15-40 capsules/m | 35-70 capsules/m | 60-100 capsules/m | 100-200 capsules/m |

| Filling Accuracy | ±1% | ||||

| Power | 1/3Phase 220/380V 50/60HZ | ||||

| Air Supply | ≥0.6Mpa | ||||

| Certification | CE, UL, ISO, FDA, GMP, CSA Compliant | ||||

| Weight | 200 Kg | 600 Kg | 900 Kg | 1200 Kg | 1600 Kg |

| Dimension(mm) | 700×900×1700 | 900×1000×1900 | 1600×870×1900 | 3600×900×1900 | 3600×1200×1900 |

GET A QUOTE