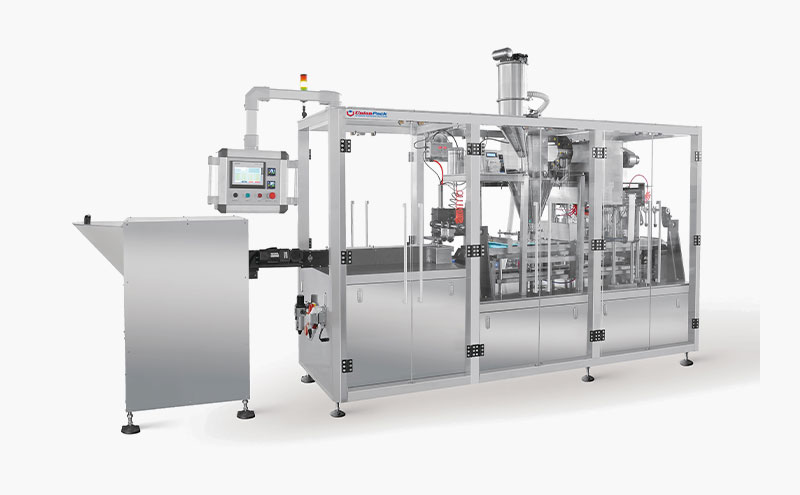

Premade cup filling sealing, including capsule coffee cup fill seal

Rotary type or horizontal type for choice

Max speed to 60 cups/min

| Capacity | 35-70 capsules/m | Air Supply | ≥0.6Mpa |

| Filling Accuracy | ±1% | Weight | 900 Kg |

| Capacity | 10-20 capsules/m | Air Supply | ≥0.6Mpa |

| Filling Accuracy | ±1% | Weight | 200 Kg |

The Cup & Bottle Filling Sealing Machine is a cutting-edge solution designed to enhance efficiency and precision in the packaging of various products, including liquids, semi-liquids, and powders. Ideal for a wide range of industries such as food and beverage, pharmaceuticals, and cosmetics, this machine delivers superior performance with its automated, user-friendly system, ensuring that your products are filled, sealed, and ready for distribution in no time.

Applications:

The Cup & Bottle Filling Sealing Machine is suitable for a wide variety of applications across multiple industries, including:

- Food & Beverage: Yogurt, milk, juices, sauces, and condiments.

- Pharmaceuticals: Medicines, liquid supplements, and powders.

- Cosmetics: Creams, lotions, serums, and powders.

1. Automated Filling & Sealing:

The machine is designed for fully automatic filling and sealing of cups, bottles, and other containers. This automation reduces the need for manual labor, streamlining your production process while minimizing errors and waste.

2. Versatile Product Handling:

Whether your products are liquids, semi-liquids, powders, or granules, the Cup & Bottle Filling Sealing Machine can handle them all. This versatility makes it a perfect choice for businesses with diverse product lines.

3. Precision Filling:

Equipped with a highly accurate metering system, the machine ensures consistent filling every time, reducing product waste and ensuring that each container has the right amount of product. The product pressure filling technology guarantees that all containers are filled without spilling, while the cup edge dust removal device ensures the containers remain 100% clean before sealing.

4. Flexible Design:

The adjustable machine setup allows it to handle various container sizes and types, making it ideal for businesses looking to package different products in different forms (e.g., cups, bottles). Its quick-change mechanism allows for easy product or packaging changes, minimizing downtime during production shifts.

5. Flavoring & Variety:

One standout feature of the Cup & Bottle Filling Sealing Machine is the ability to add liquid and solid flavorings to the containers, enhancing product appeal and variety. This feature is particularly beneficial for businesses in the food and beverage industry, offering a way to differentiate products with unique flavors or supplements.

6. User-Friendly & Easy Maintenance:

With its intuitive human-machine interface (HMI), the machine is easy to operate, even for users without extensive technical experience. Its servo-driven system ensures smooth and quiet operation, reducing the need for frequent maintenance. The design allows for easy dismantling and cleaning, making it convenient to switch between different products or packaging types.

7. Efficiency & Cost Reduction:

By automating the entire filling and sealing process, the machine helps cut down production costs significantly. Its large, self-developed storage compartment for empty containers ensures continuous operation without frequent interruptions for refilling, further optimizing productivity.

GET A QUOTE