Box Packing Solution: Efficient, Flexible, and Automated Packaging for Various Industries

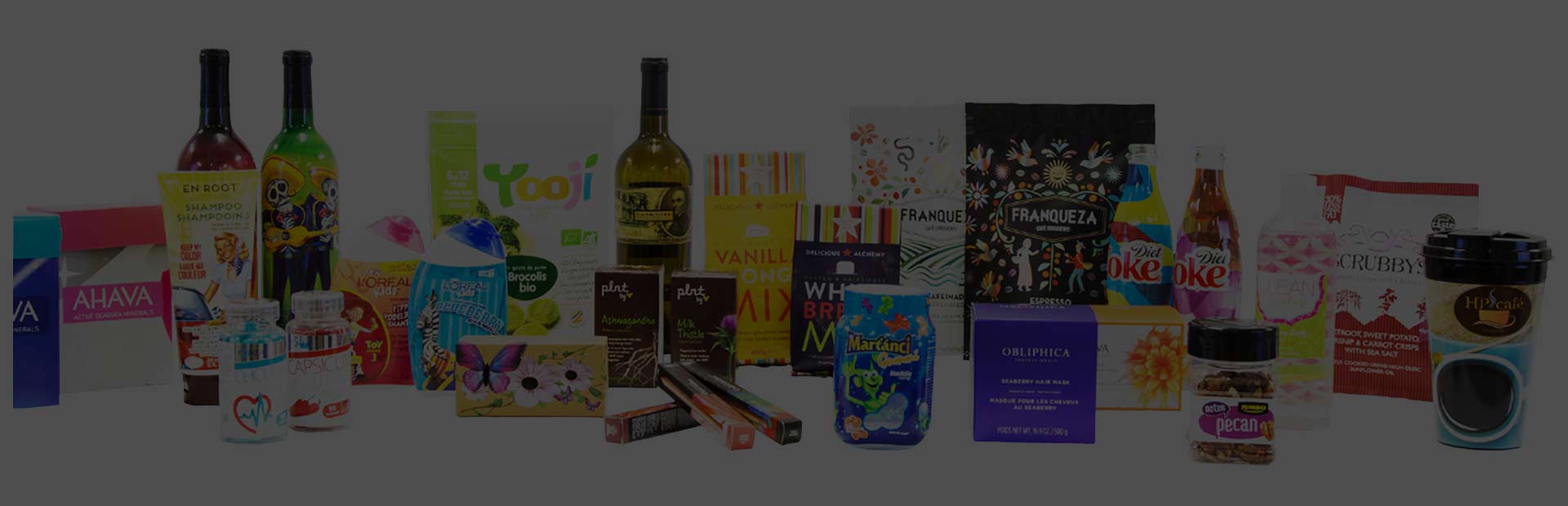

In today’s fast-paced production environment, packaging solutions need to be reliable, efficient, and adaptable to various product types. Whether you're in the daily necessities, cosmetics, pharmaceuticals, food, or stationery industries, having a robust and versatile packaging solution is essential. That’s where our Box Packing Solution comes in—providing streamlined, automated packaging for a wide variety of products and packaging requirements.

What is a Box Packing Machine?

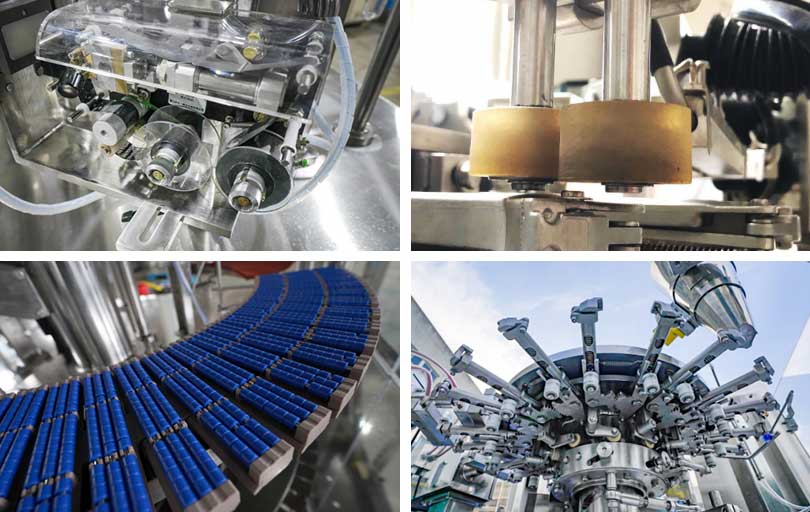

A Box Packing Machine, also known as a carton packing machine, cardboard packing machine, case packer machine, or tape packing machine, is an intelligent, automatic system designed to pack unpacked products or small pre-packaged items into transport cartons or boxes. Unlike traditional manual packing, this solution automates the process, improving efficiency, reducing labor costs, and ensuring consistent product quality.

How It Works:

Our Box Packing Machines are equipped with high-speed distribution devices that automatically load various products into boxes, ensuring they are securely packed and ready for shipment. The machine typically includes the following functions:

1.Carton Forming/Opening: The machine automatically forms and opens the carton boxes, eliminating the need for manual labor in setting up the containers.

2.Product Sorting and Loading: Products are automatically sorted and loaded into the open cartons in a specific arrangement and quantity.

3.Carton Sealing: Once the products are loaded, the machine seals the carton with adhesive tape or another sealing mechanism to secure the contents.

4.High-Speed and Efficient: The system ensures that products are packed quickly and efficiently, reducing bottlenecks in your production line.

Key Features of Our Box Packing Solution:

●Flexible Application: Our Box Packing Machines are designed to handle a wide range of products. From plastic flat bottles, round bottles, and irregularly shaped containers to glass bottles, square cans, and paper cans, the machine can accommodate different packaging sizes and shapes.

●Automatic Sorting: The machine can automatically sort the products before packing, streamlining the entire packing process.

●Compact and Space-Saving Design: With a novel and compact structure, our box packing solutions are designed to maximize space in your production facility while maintaining high efficiency.

●User-Friendly Control System: The machine is controlled by PLC (Programmable Logic Controller) and features a touchscreen interface, making it simple to operate and adjust settings. The intuitive controls ensure that even new operators can use the system with minimal training.

●Safety Features: Our Box Packing Machines come with built-in safety mechanisms, including an alarm stop for missing bottles and a no bottle, no packing safety device. These features ensure the integrity of your product and prevent waste during the packing process.

●Ease of Integration: Our machines are designed to work seamlessly with your existing production line. Whether you need to integrate with automated filling machines, labeling systems, or conveyor belts, our Box Packing Solution is adaptable to your workflow.

Advantages of Our Box Packing Solutions:

●Increased Productivity: By automating the packing process, our solution allows you to significantly increase production speed, reducing labor costs and minimizing the risk of human error.

●Consistent Quality: With high-precision technology, each carton is packed uniformly, ensuring that your product is consistently presented to customers.

●Easy Maintenance: The simplified transmission system and PLC-controlled operations ensure that the machine has low maintenance requirements and high reliability, reducing downtime and maintenance costs.

●Cost-Effective: Automated packing reduces manual labor, speeds up the process, and minimizes packing material wastage, resulting in substantial cost savings over time.

Applications:

Our Box Packing Machines are highly versatile and can be used across a wide variety of industries, including:

●Food and Beverages: For packing snack boxes, canned foods, beverages, condiments, and frozen products.

●Cosmetics and Pharmaceuticals: For packing skincare products, medicines, and supplements.

●Daily Necessities: For packaging household items, cleaning products, and personal care goods.

●Stationery: For packing office supplies, stationery sets, and other retail products.

Why Choose Our Box Packing Solution?

1.Reliable and Durable: Built to last with high-quality materials, our machines ensure a long operational lifespan with minimal maintenance.

2.Customizable to Your Needs: Whether you're packing small or large quantities, our solutions can be tailored to meet your specific product and packaging requirements.

3.Scalable for Growth: As your production needs grow, our Box Packing Machines are scalable, allowing for easy upgrades and system expansions.

Get Started with Unionpack’s Box Packing Solutions Today!

For manufacturers looking to improve efficiency, reduce labor costs, and enhance the overall packing process, Unionpack’s Box Packing Solutions offer the ideal combination of flexibility, efficiency, and automation.

Contact us today to discuss how our Box Packing Machines can streamline your production process, save time, and improve your bottom line. We look forward to helping you achieve your packaging goals with our advanced, intelligent packaging technology!

Inquire Now