| Encasing Speed | 80-100 Boxes/min | Power supply | AC220V/380V 50Hz |

| Quality requirement | 250-350 g/㎡ | Total power | 6.0 KW |

| Working pressure | ≥ 0.6 Mpa | Overall dimension | 6500×2000×1800mm |

| Air consumption | 20 m³/h | Machine weight | 3000 kg |

| Encasing Speed | 80-100 Boxes/min | Power supply | AC220V/380V 50Hz |

| Quality requirement | 250-350 g/㎡ | Total power | 6.0 KW |

| Working pressure | ≥ 0.6 Mpa | Overall dimension | 6500×2000×1800mm |

| Air consumption | 20 m³/h | Machine weight | 3000 kg |

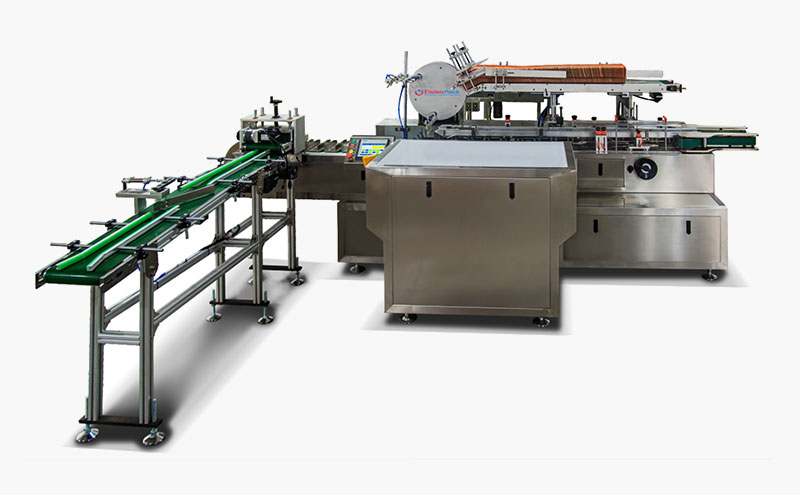

1. The UN-200GZH automatic cartoning machine is fully enclosed in stainless steel, with a closed circuit and pneumatic construction, making it more user-friendly and compliant with GMP requirements. The drive unit is located at the rear of the machine, completely open on the operator's side, making it easy to operate. The innovative and compact design, coupled with ergonomic construction, allows operators to get as close as possible to the equipment and clean it easily. All operations are simple and easy to perform.

2. The equipment's outer casing is wrapped in high-quality 304 stainless steel, and the operating area is protected by a combination of aluminum alloy and tempered glass doors, providing safety for the operator.

3. The machine uses a horizontal cartoning method, using suction cups and the principle of a crank-slider mechanism to place the cartons into the rotating chain. The rotating chain operates intermittently in the same direction, and both the cartons and products are packed and boxed in a lying down manner.

4. The fixed carton storage device can accommodate 300 cartons to ensure a steady supply.

5. The operating system uses a human-machine interface touch screen to communicate with the machine, allowing adjustments to be made to various work station programs, monitoring machine production status, and displaying fault alarms.

6. The program uses a PLC for full automatic monitoring, with a photoelectric detection mechanism that can issue alarms for missing materials, cartons, jammed cartons, and overloaded feeds, ensuring 100% output of qualified finished products. The count is automatically displayed on the screen.

7. The machine uses multiple highly reliable mechanical overload protection devices, allowing it to protect itself from sudden events during operation, reducing machine damage.

8. The UN-200GZH automatic cartoning machine can reliably pack items with stable or regular external shapes within a certain size range into specific cartons and seal them for delivery. It is suitable for the packaging of various drugs, foods, cosmetics, and other related products.

9. The UN-200GZH automatic cartoning machine can serve as a terminal machine for upstream machines to complete product cartoning tasks, as well as an upstream machine for downstream machines such as strapping and box loading. It can also be used as a stand-alone machine.

10. The UN-200GZH automatic cartoning machine can meet users' requirements for changing product specifications. It has a small number of mold types, a short mold production cycle, easy assembly and debugging, and can meet both users' needs for large-scale production of a single product and for small-scale production of multiple products.

The UN-200GZH automatic cartoning machine is a reliable and efficient packaging machine suitable for a variety of industries. Its innovative design, user-friendly interface, and automatic monitoring system make it easy to operate and maintain. Whether as a stand-alone machine or as part of a production line, the UN-200GZH automatic cartoning machine is an excellent choice for anyone looking to improve their packaging process.Use of environmental conditions and working conditions

a. Ambient temperature: 10~30°C

b.Power supply voltage: 180V/50Hz

c.Air source pressure: 0.5-0.7Mpa

d.Air source flow:15-20 m3/h

Carton paper quality 250~350/g㎡ white cardboard, 250~400/g㎡ gray cardboard

Since the quality of the packaging carton directly affects the final packaging quality and the normal operation of the equipment, this machine has high requirements for the quality of the packaging carton, not only for the paper quality to meet the above requirements, but also for the production process of the carton, in order to meet the needs of the equipment process.

|

Model |

UN-200GZH Automatic Cartoning Machine |

|

|

Encasing Speed |

80-100 Boxes/min |

|

|

Box |

Quality requirement |

250-350 g/㎡ |

|

Dimension range |

(100-300)×(100-200)×(60-100)mm(L×W×H) |

|

|

The dimensional range of all boxes that can be packed |

(45-400)×(15-260)×(15-100)mm(L×W×H) |

|

|

Compressed air |

Working pressure |

≥ 0.6 Mpa |

|

Air consumption |

20 m³/h |

|

|

Power supply |

AC220V/380V 50Hz |

|

|

Total power |

6.0 KW |

|

|

Overall dimension |

6500×2000×1800mm(L×W×H) |

|

|

Machine weight |

3000 kg |

|

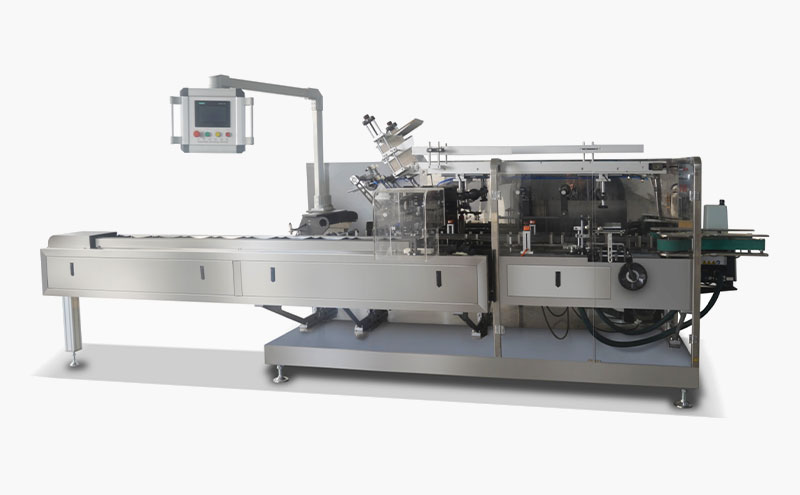

| Encasing Speed | 33-120 Boxes/min | Power supply | AC220V/380V 50Hz |

| Quality requirement | 250-350 g/㎡ | Total power | 1.5 KW |

| Working pressure | ≥ 0.6 Mpa | Overall dimension | 4500×1550×1800mm |

| Air consumption | 20 m³/h | Machine weight | 1500 kg |

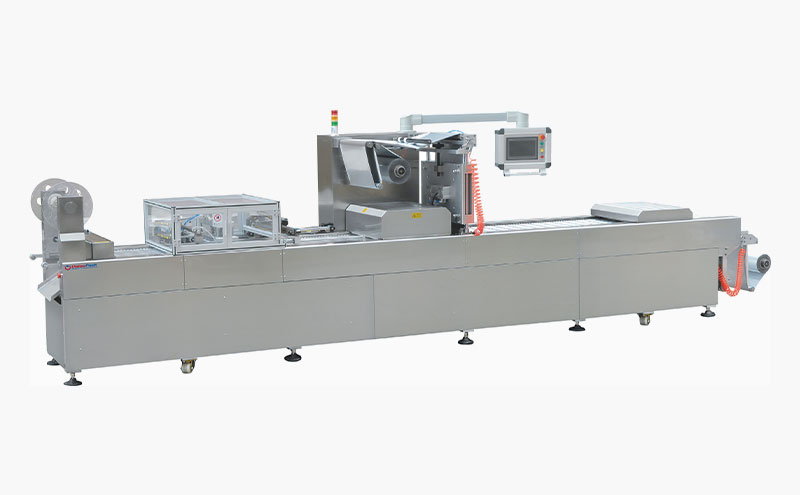

| Width of upper film | 398 mm | Vacuum | ≤ 200 Pa |

| Width of lower film | 423 mm | Compress air | ≥ 0.6 Mpa |

| Speed | 4-6 p/min | Capacity | 12-18 KW |

| Power | 380 V/50 Hz | Dimensions | 2250 kg |

GET A QUOTE