| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

Packaging plays a vital role in product protection, shelf life, and brand presentation. The two most common packaging machines used by the industry are the Vertical Form and Seal Machine (VFFS) and the Horizontal Form and Seal Machine (HFFS). While both automate the packaging process, they differ in design, functionality, and applications.

This article explores the differences between Vertical Form and Seal Machine and Horizontal Form and Seal Machine, focusing on Vertical Form and Seal Machine, its benefits, and how it compares to horizontal form and seal machines.

A Vertical Form and Seal Machine is a packaging system that forms a roll of film into a bag in a continuous vertical motion, then fills the bag with the product and seals it. These machines are widely used for packaging:

Snacks (chips, nuts, candies)

Granular products (powders, grains, seeds)

Liquids (sauces, beverages)

Pharmaceuticals (pills, capsules)

Space saving – vertical operation, takes up less space.

High speed packaging – suitable for small and medium-sized products.

Various packaging styles – pillow bags, gusseted bags or stand-up bags can be produced.

Reduce material waste – use pre-rolled film to reduce excess packaging.

Horizontal form-fill-seal machine can form bags or trays horizontally for larger or irregularly shaped products. Common applications include:

Frozen foods (pizza, vegetables)

Bakery goods (bread, cookies)

Medical devices (syringes, test kits)

Non-food items (toys, hardware)

Better for larger products – more efficient handling of larger or rigid items.

Tray sealing capability – can form rigid or semi-rigid packaging.

Higher production capacity – typically used in high-volume packaging lines.

III. Vertical vs. Horizontal Sealers: Key Differences

| Features | Vertical Form Fill Seal (VFFS) Machines | Horizontal Form Fill Seal (HFFS) Machines |

| Direction | Vertical operation (top to bottom) | Horizontal operation (side to side) |

| Best suited for | Small, granular, or liquid products | Large, bulky, or irregularly shaped items |

| Packaging Type | Pillow bags, stand-up pouches | Trays, flow bags, pouches |

| Space Requirements | Compact, for limited spaces | Requires more floor space |

| Speed | High speed, for small items | Slower speed, but can handle larger products |

| Flexibility | Better for lightweight products | Better for heavy or rigid packaging |

Vertical or horizontal sealer depends on your product type, production speed and packaging requirements.

For powders, granules or liquids (e.g., coffee, snacks, detergents)

Limited space in production facilities

High-speed, cost-effective packaging

For large or oddly shaped items (e.g., frozen foods, medical devices)

Need rigid or tray packaging

Large-volume production of larger products

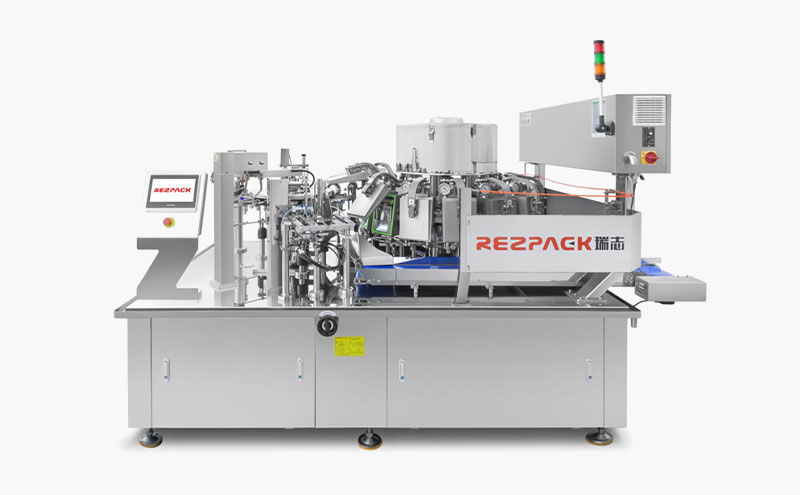

After 32 years of intensive cultivation in the packaging industry, Ruizhi has developed and produced a variety of packaging machines for a variety of applications and has close ties with the international market. The brand's equipment is exported to more than 40 countries and serves more than 3,000 domestic and foreign companies. Ruizhi has partners in Southeast Asia, Europe and the United States, including internationally renowned brands such as Nestlé, Arvato, Hershey, and Colgate.

We are well aware that different companies have different needs and adopt customized solutions. We can also select the right equipment for you according to your needs and create professional equipment for your production.

Vertical full-cap sealers and horizontal cap sealers each have their own unique advantages depending on the specific application. Vertical fill-and-seal machine are ideal for small, granular or liquid products, and their compact design combines speed and efficiency. Horizontal fill-and-seal machine, on the other hand, are more suitable for larger items that require tray or pillow packaging.

By understanding the differences between these two packaging systems, companies can choose the right machine to optimize efficiency, reduce waste, and improve product appearance.

| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

| Bag Width Range | 180-300 mm | Weight | 1800 kg |

| Bag Length Range | 150-450 mm | Total power | 3.62 kw |

| Filling weight | ≤ 2500 g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 50 bags/min | Dimensions | 2080 mm*1720 mm*1650mm |

| Bag Width Range | 240-400 mm | Weight | 2500 kg |

| Bag Length Range | 150-600 mm | Total power | 3.62 kw |

| Filling Range | ≤ 5000g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 30 bags/min | Dimensions | 2150 mm*2020 mm*1700 mm |

GET A QUOTE