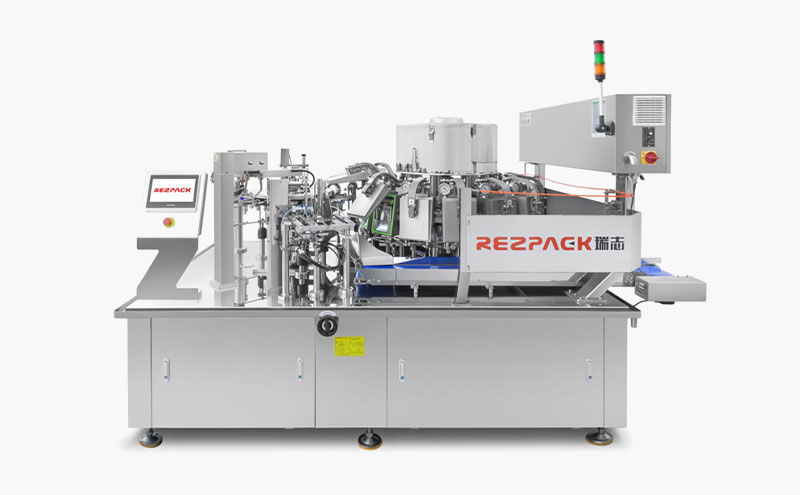

| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

Understand the advantages of conveyors to unlock the code for efficient production and logistics.

1.High - Efficiency Material Transportation:Conveyors are capable of achieving continuous material conveyance, significantly enhancing transportation efficiency. Take large - scale e - commerce warehouses as an example. Goods are rapidly transferred among different areas via conveyors, from the sorting area to the packaging area and then to the shipping area. In contrast to manual handling, conveyors can transport several tons or even dozens of tons of goods per hour, substantially accelerating the goods - processing speed and meeting the large - scale order demands of e - commerce operations.

2.Reduction of Labor Costs:With the utilization of conveyors, enterprises can cut down on a large amount of manual handling work. In traditional manufacturing workshops, a great number of workers were previously needed to transport raw materials and semi - finished products. Nowadays, conveyors can take on the majority of this work. This not only reduces the labor input but also mitigates the issue of efficiency decline caused by manual fatigue. In the long run, it saves enterprises a considerable amount of labor costs.

3.Enhanced Production Accuracy:Conveyors operate along preset paths and at set speeds, ensuring the accuracy and stability of material transportation. On electronic component production lines, minute and precise components are conveyed through conveyors, which can prevent collisions and damage that might occur during manual handling, guaranteeing that the components are accurately delivered to the designated positions and improving the production quality and consistency of products.

4.Optimized Working Environment:In some harsh working environments, such as those with high temperatures, dust, or chemical pollution, the use of conveyors enables workers to stay away from dangerous areas. For instance, in cement plants, conveyors are in charge of transporting cement raw materials and finished products. Workers don't have to frequently handle materials in a dust - filled environment, reducing the risk of occupational diseases and improving the working environment.

5.Adaptability to Diverse Production Demands:There are various types of conveyors, such as belt conveyors, roller conveyors, and chain conveyors, which can be selected according to different material characteristics and production scenarios. In the food - processing industry, where strict hygiene requirements are imposed, food - grade belt conveyors can be chosen. In the heavy - industry sector, where large and heavy materials need to be transported, chain conveyors are more appropriate, meeting the diverse production requirements of various industries.

6.Facilitation of Production Process Integration:Conveyors can be seamlessly integrated with other production equipment and become an essential part of the automated production line. In an automobile manufacturing plant, conveyors connect all the production processes, from the assembly of parts to the vehicle's final off - line. This makes the entire production process more compact and efficient, promoting the automation and intelligent development of production.

| Bag Width Range | 80-240 mm | Weight | 1500 kg |

| Bag Length Range | 150-370 mm | Total power | 3.02 kw |

| Filling weight | ≤ 1500g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 60 bags/min | Dimensions | 1860 mm*1520 mm*1550 mm |

| Bag Width Range | 180-300 mm | Weight | 1800 kg |

| Bag Length Range | 150-450 mm | Total power | 3.62 kw |

| Filling weight | ≤ 2500 g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 50 bags/min | Dimensions | 2080 mm*1720 mm*1650mm |

| Bag Width Range | 240-400 mm | Weight | 2500 kg |

| Bag Length Range | 150-600 mm | Total power | 3.62 kw |

| Filling Range | ≤ 5000g | Compress air | ≥ 0.4 m³/min |

| Max Speed | ≤ 30 bags/min | Dimensions | 2150 mm*2020 mm*1700 mm |

GET A QUOTE